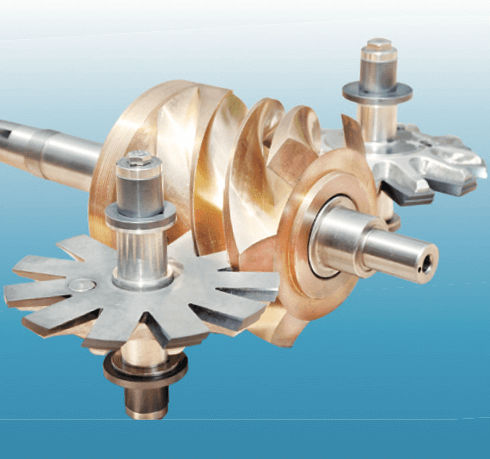

Oil-free technology reduces expenditures in these ways:

– Saving energy due to hot air discharge

The superior cooling capability of lubricating water ensures that the heat is removed efficiently at the source gives more air per kW of power. The operation temperature is about 55℃, there is no need to be cooled and discharged directly.

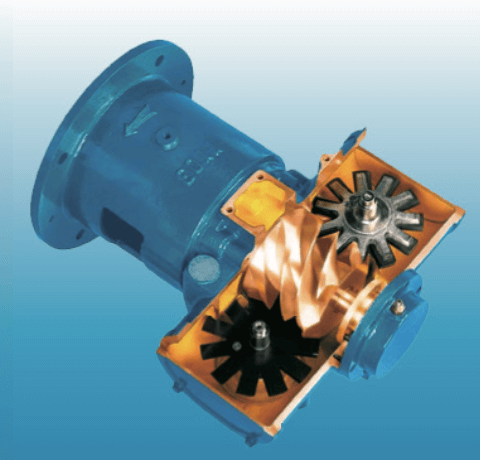

– Saving the costs of extra energy to combat pressure drop due to oil air separation unit.

For the oil-lubricated screw air compressor, the oil air separation unit resistance leads to pressure loss. Power consumption increases by 0.3%~0.5% for every increase of pressure drop of 0.1bar

– High compression efficiency due to low temperature ideal isothermal compression

For the oil-lubricated screw air compressor, high Interstage and exhaust temperature, rise every 10 ℃, power consumption will increase 3% as a result.

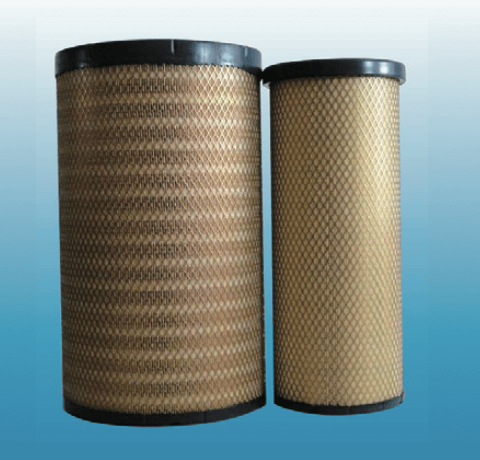

– Cutting maintenance costs and treating oily condensate costs

Avoiding expensive oil, oil-filter, air oil separator, oil cooler costs.

Low temperature reduces the stress on components ensuring long life.