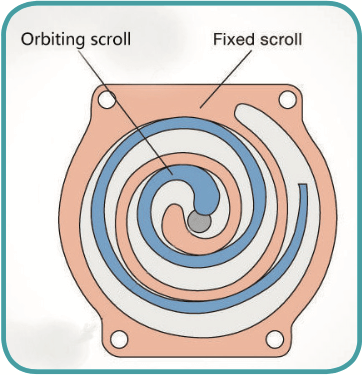

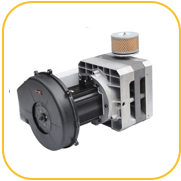

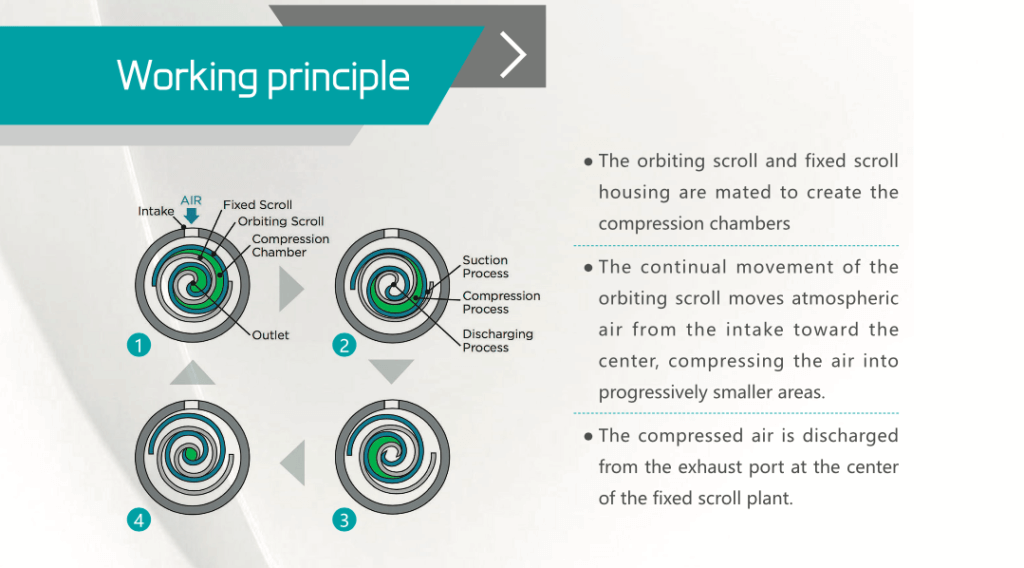

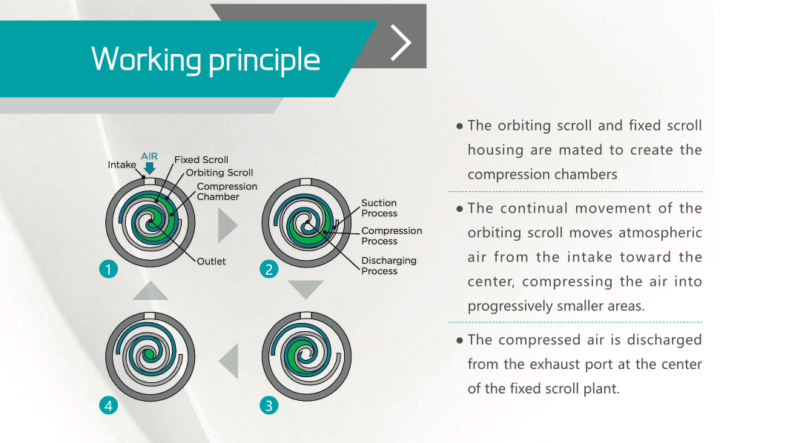

The working of scroll air compressors occurs in relatively three phases. When the moving scroll is rotated around the stationary scroll, the gas pockets are formed, and thus the air gets trapped in these pockets, which then further passes to the below discussed three phases.

Suction phase:

In this first shaft revolutionary phase, the motion scroll moves around the orbit of the fixed spiral; as in result, it creates the gas pockets. And when the gas pocket is formed, the suction port endows the outside air to get in a trap with these air spaces or gas pockets. When the first rotatory revolution is completed, the adjacent surfaces meet at the ends so that the air can’t move outside.

Compression Phase:

This is the second shaft revolutionary phase; in this phase, the rotatory scroll again starts moving around the fixed scroll. As the air is sealed in the gas pockets, further motion causes the air to move to the inner gas pockets and in turn, the volume of the air is reduced and the air gets compressed. When this second phase completes, the maximum gas is compressed in the gas pockets.

Discharge phase:

This is the third shaft revolutionary phase; in this phase, the compressed gas which is present at the most inner pockets moves toward the discharge port with the help of further motion of scrolls. The compressed air then discharges out through the port which results in making the volume in gas pockets condensed to zero.

Once this procedure cycle completes, the three phases, namely suction phase, compression phase, discharge phase, again transpire instantaneously at comparative sequence.