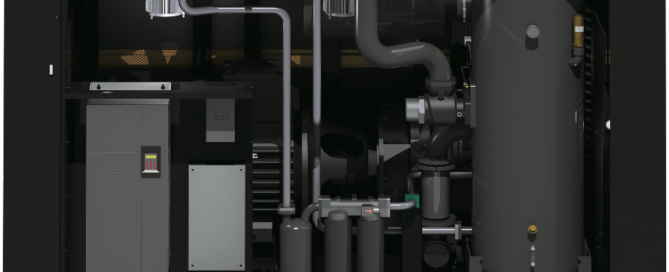

Best Practices For Using Compressed Air Systems

Compressed air is used in many applications. However, under-designed systems are the leading cause of compact air problems resulting in reduced productivity and quality. The key to having a cost-efficient, productive system lies with the proper management of compressed air systems. A basic understanding of how an air compressor works and some knowledge on Best