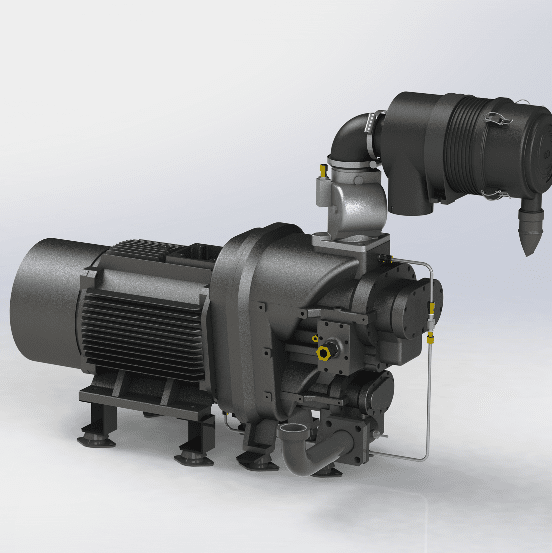

Two-stage compression technology

Two-stage compressor(or Dual-stage compressor) energy-saving 5%~13% over equivalent sized single-stage compressors. But why?

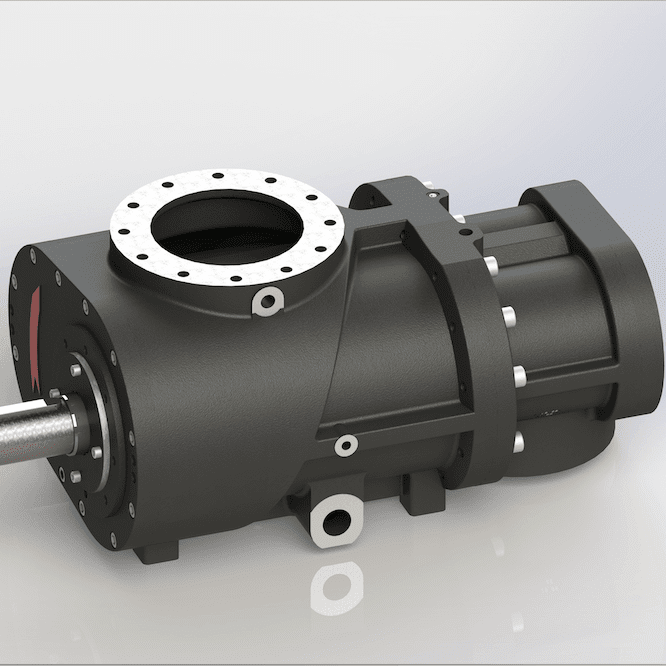

– Adopt two-stage compression to attain reasonable pressure distribution and reduce each compression ratio, which can achieve the compressor’s power savings.

In a single-stage compressor operating at 100 PSIG at sea level, the compression ratio is 7.9 to 1 (in absolute terms). But a two-stage compressor operating at the same pressure will have a compression ratio of 2.8 to 1 in each stage (2.8 is the square root of 7.9) .

– Low compression ratio reduces the internal leakage and improve volumetric efficiency.

– Low compression ratio reduces the bearing load, improve the bearing life and extend the life of the host.