For the screw type air compressor, it can be divided into two kinds: double-screw/twin-screw type or single-screw/, we will talk about how single-screw air compressor work.

The basic structure of the Single Screw Air-end

The basic structure of the Single Screw Air-end

The advantages of a Water-lubricated/water-injected Oil-free Air Compressor are reflected in the Single-screw Air-end, and the advantages of the Air-end are reflected in its basic structure.

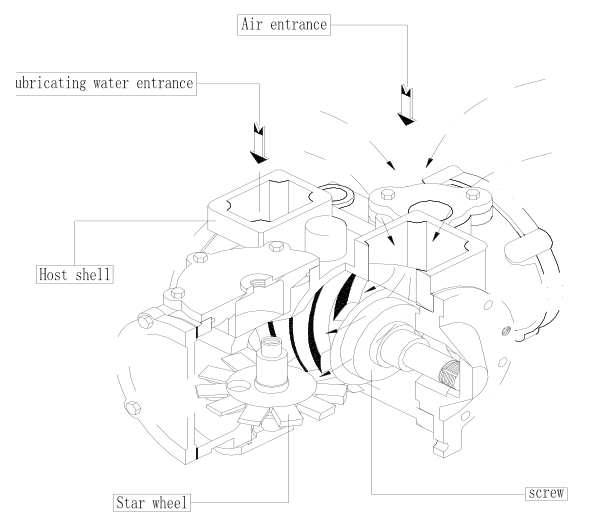

The single screw air end consists of one screw rotor and two symmetrical star wheels, which installed in the shell of the screw air end (Figure 1). The space surrounded by the screw channel, the inner wall of the shell, and the tooth of star wheels forms the air compressor’s working volume.

The screw rotor is direct driven by the motor, and the screw rotor drives the star wheels.

The air is sucked into the screw channel from the inlet on the top of the air-end, then after compressing, the compressed air exhausts through the outlet of the air-end.

There is also a lubricating water inlet on the top of the air-end. The water injected into the screw air-end plays the role of lubricating, sealing, cooling, and denoising.

Working principle of the Single Screw Air-end

Working principle of the Single Screw Air-end

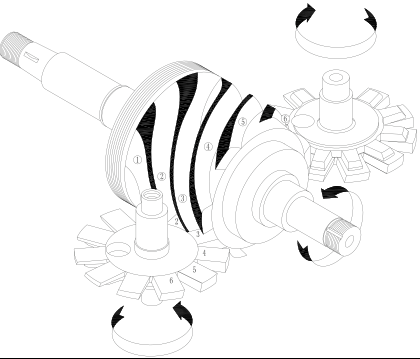

The working principle of the Single-screw air compressor is similar to the reciprocating air compressors (Volume type): The “cylinder” turns into a curved spiral groove and the depth of groove continuous change. The “Piston” turns into the star wheels. When the screw rotor rotates, the star wheels also rotate relatively, the closed volume gradually reduces, so the air is compressed.

When the screw rotor counterclockwise rotates around its axis, it drives two-wheels rotation. The two-wheel symmetrical orientation configuration, so one rotates clockwise and one rotates counterclockwise

For the convenience of the description, we note numbers for the star wheel and the channels. At the end of the compressing process of the no.1 channel, the compressed air will be exhausted soon. While the no.2 channel will be closed by the no.2 star-wheel teeth, the air inside this channel is being compressed. While the no.3 channel is sucking air and will be closed by no.3 teeth soon.

Main advantages of the Single-screw Air Compressor

Main advantages of the Single-screw Air Compressor

- From the figure, we find that when the no.1~3 channels are working, the no.4~6 channels are doing the same work at the same time. That is, each screw channel in the rotor works twice on both sides during one rotation, so the volume efficiency is higher compared with other types of compressors.

- The axial high-pressure side of the screw rotor is closed, which means the axial force is an internal force, so the screw rotor does need to bear axial force. Besides, as the symmetric star wheels on both sides of the screw rotor, which offsets the radial opposite force, so that the screw rotor force completely in a balanced state.

- The frictional force between the channel and the friction pair of star wheels is parallel to the gas force acting on the star wheels, so the gas force has no effect on the friction force, which is a key factor for hydrodynamic lubrication. and that is why the service life of star-wheels is very long.

Leave A Comment