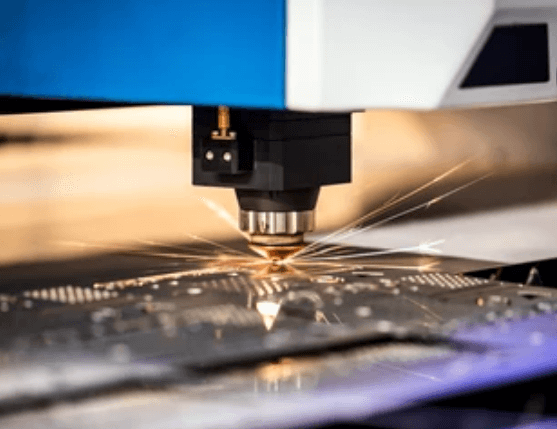

Laser Cutting Machines are in high demand around the globe. They can cut material in the most precise, quick, and efficient way. Thus, unlocking various domestic and industrial applications.

Initially, these laser cutting machines were expensive to use and maintain. Besides, they were not very efficient. This forced laser cutting machine manufacturers and engineers to develop innovative ideas to improve the result and reduce costs.

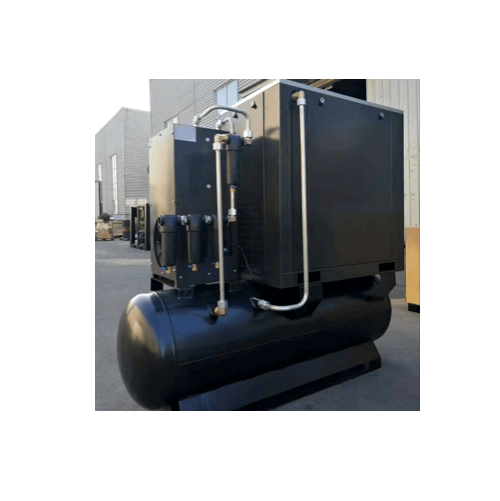

This is where the idea of using air assistance kicked in, which required air compressors to work.

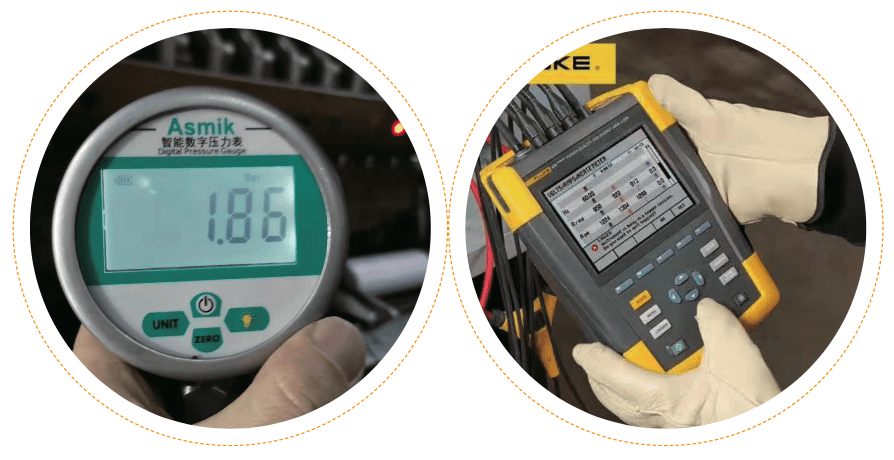

Thus, the high usage and maintenance cost of laser cutting, the rising demand of its machines, and their reliance on compressed air enabled the air compressor manufacturers to customize their product to meet the demanding requirements, reduce cost and improve the cutting efficiency.

Although Air Assisted Laser Cutting machines are available in various types and sizes, they all need a pressurized gas source as power when working.