Air Compressor for Fermentation Industry

Air compressors are the most essential component of the fermentation industry. From the processing to the packaging of food and beverages, compressed air is a crucial element. Compressed air provides sufficient oxygen to fermentation bacteria for the production of various products. In the absence of adequate oxygen, bacterial growth retards and the production of desired products can’t be accomplished.

A variety of air compressors are used for various purposes in the fermentation industry. To have a more clear idea about the application of air compressors in the fermentation industry, read the article till the end.

Do you need

Do you need

We have more than 30 years’ experience.

The function of Air Compressor in Fermentation Industry

Air compressors perform a variety of functions in the fermentation industry. Air compressors are frequently used in the following are the areas of fermentation industry:

Sorting

Air compressors sort the ingredients for the production of desired products and move them forward for further processing. Powdered ingredients are usually hard to sort. Compressed air sorts and forces them into pipes.

Peeling and Cutting

Peeling and cutting of fruits and vegetables are also accomplished with the help of high-pressure compressed air. Pressurized air removes the peel of fruits and vegetables. It also cracks the shells of nuts and pulls out their peel.

Mixing

On a large scale, the mixing of dry ingredients is achieved efficiently by air compressors. The mixing process is carried off gently for preventing damage to the ingredients.

Filling

Compressed air also assists in evenly distributing fillings into the cakes, pastries, pie, and cookies. The fillings look smoother and more consistent when filled with compressed air. The filling process by air compressors also prevents the wastage of the fillings.

Cooling

Air compressors are also used for cooling baked or cocked products in the fermentation industry. A steady stream of compressed air quickly cools the food that leaves the oven and makes it ready for packaging.

Freezing

Air compressors are used in refrigerating plants for freezing purposes. A cold and dry stream of compressed air cools and freezes various processed foods and beverages in the fermentation industry.

Packaging

Time-taking and strenuous process of packaging is not done easily by air compressors. Compressed air conveniently cleans cans, bottles, containers, and bags and packs food and beverages in them.

Types of Air Compressor Used in Fermentation Industry

Fermentation is a vast industry. Various fermentation processes employ different types of air compressors. Following three types of air compressors are used in the fermentation industry:

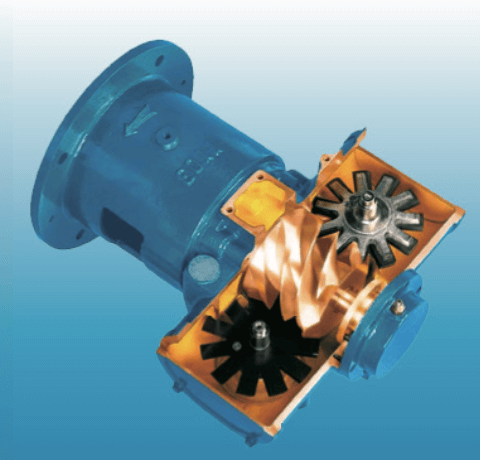

Rotary Screw Compressor

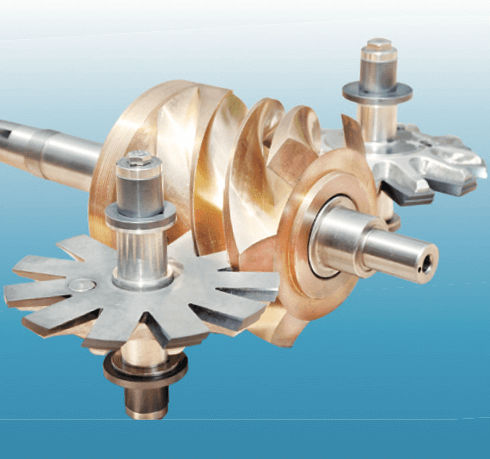

Rotary screw compressor operates as a positive displacement compressor. In this type of compressor, two meshing oil-folded helical screws referred to as rotors, are used to compress air. One of the two rotors is the male rotor and the other is the female rotor.

While rotating, the leading strip of the male rotor approaches the contour of the female rotor and traps air. As the air moves down the grove of the female rotor, the volume of air is compressed. The male rotor approaches the end of the groove and the trapped air is released via the airend. The rotary screw compressor is also equipped with an internal oil-cooling system to maintain the internal temperature.

This type of compressor is used for sorting and peeling raw materials, filling cakes, pastries, and cookies, mixing, and freezing food products.

Reciprocating Compressor

The reciprocating compressor also functions as a positive displacement compressor and reduces the volume of air by increasing the pressure.

This type of compressor takes in an adequate quantity of air in large cylinders. The crankshaft drives the pistons in cylinders and the pressure over the air increases. Increased pressure compresses the air and reduces its volume.

Reciprocation compressors are either water-cooled or air-cooled. Mostly they are also lubricated for smooth functioning by oil, but non-lubricated compressors are also available. Variable capacities and pressures are also available. These compressors are often used for the freezing and packaging of fermented food.

Centrifugal Air Compressor

Centrifugal compressor operates as a dynamic compressor. These types of compressors increase the velocity of air by a rotating impeller. The kinetic energy of fast-moving air is used to elevate the pressure by slowing it down with the help of a diffuser.

Centrifugal air compressor is designed for continuous use and has a higher capacity than other types of compressors. It is an oil-free compressor and thus requires little maintenance. This compressor is used for various processes of aerobic fermentation where a continuous flow of oil-free air is required.

Common Equipment for the Fermentation Applications

Air compressors are widely used in the fermentation industry for the effective processing of food and beverages to meet market demands. Compressed air provides clean, fresh, and quality food by improving the efficiency, productivity, and cleanliness of various processes of food production. Consult the experts to learn about the type of compressor that will suit your fermentation product. With the proper use of the right type of air compressors, your fermentation product will surely hit the market.

- If the compressed air will be applied to the fermentation industry, we suggest using a 100% Oil-free type air compressor with an air dryer and filters.

- If the requirement for dew point is -20~-40℃, we suggest using a adsorption air dryer.

- Contact BENEAIR to get a proposal.

Related Products

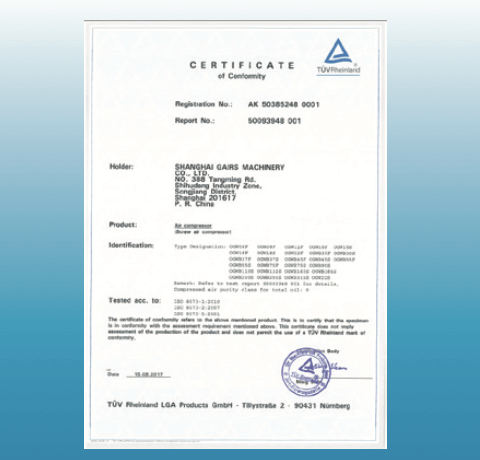

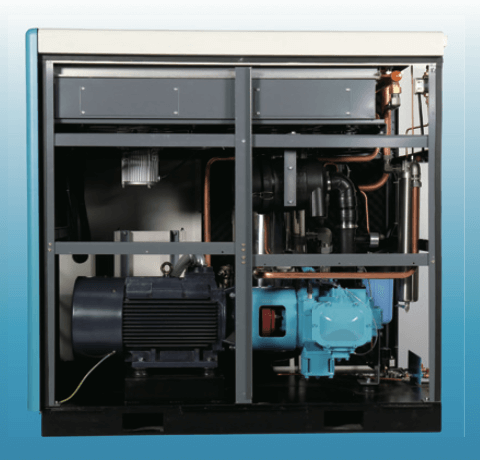

100% OIL-FREE

More than 20 years experiences in Water-lubricated Oil-free technology

Germany Rhineland TUV Class 0 Oil-free Certification

RELIABLE

More than 30 years Single Screw Technology

Most balance and reliable structure

Low temperature(< 55℃) reduces the stress on components

LOWER MAINTENANCE

Without Oil Air Separation Unit

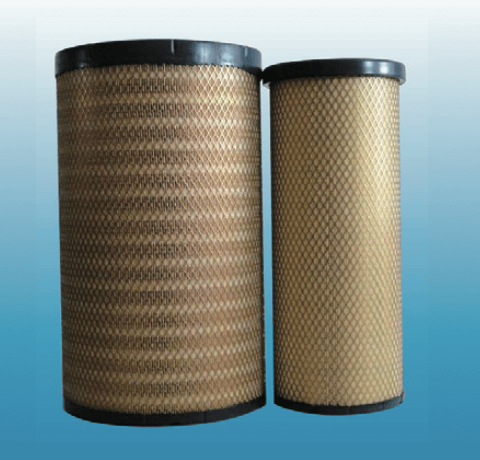

Consumable parts are only air and water filter elements

$100~$300/year

ENERGY SAVING>30%

Ideal isothermal compression and no heat waste(<55℃)

Most Advanced VSD and Two-stage compression technology

SUPER QUIET

Super dynamic balanced system

The motor and screw are directly connected

Sound absorbing materials are also used in the shell

AIR END

Optimal profile

Double stage energy saving more than 10% than single stage.

PM MOTOR

Direct Drive

Class 1 PM motor, Power factor: >95%, Oil-cooled type can be customized

VSD CONTROL

Automatic operation

Dynamic display all operation parameters, prevent accidents by the alarm.

EASY-MAINTENANCE

Patent technologies

Filters can be easy replaced in half an hour. Oil can be completely replaced.

OIL SYSTEM

Minimum pressure drop

Patent oil storage device can guarantee the oil supply of the air end after a long shutdown.

How to choose the right air compressor?

Air Compressor Sizing

Whether you're starting your business or adding a new compressor to your setup, you need to choose the

Meeting Standards for Compressed air for Electrical Bus or Railway

You may not be aware of the fact that your everyday smooth railroad venture exclusively relies upon

What Is Ambient Pressure and Why Is It Important?

Many screw-type air compressors have an adjustable regulator screw. This screw controls the pressure of the compressed air

What to Look for in a Dental Air Compressor?

A dental compressor is a device that provides compressed air to any equipment requiring compressed gasses. It supplies

Air Compressor Horse Power

Most people assume that all air compressors are the same; however, this is not true. The horsepower of

Air-Cooled vs. Water-Cooled Compressor

In the procedure of compression of gases, the air compressor creates a lot of heat. The air compressors

We replaced 21 piston type compressors with one 40bar 10cubic Screw type compressor.

No more noise, no more spare parts and high maintenance fee.

We began to use their oil free type products since 1998, the products are very reliable.

Their Water-lubricated Screw Air Compressor can ensure the 100% oil free and clean compressed air for our processing, and ensure the high quality of our products.

The oil free type screw air compressor energy saving 38.6% compared with our used air compressor, and saving 25.8% compared with the new oil lubricated type screw air compressors.

“Class 0 oil-free air compressor guarantee the best quality of our end products”

“Electrical costs and maintenance fee is significantly reduced.”