Air Compressor for Electronic Industry

Countless industries use air compressors for many applications, including powering various electrical and electronic devices. They power various electrical tools including, nail guns, air staplers, air sanders, and spray guns.

Besides home and construction applications, compressed air also provides kinetic energy to power pneumatic devices, primarily in electronic manufacturing, including air-operated lathe chucks, pneumatic robotic arms, or other production equipment, to convey or cool components during production and pressure clean parts.

The electronic Manufacturing Industry is a sensitive industry that requires high-tech machinery, high-skilled staff, a sterile environment, and strict production standards.

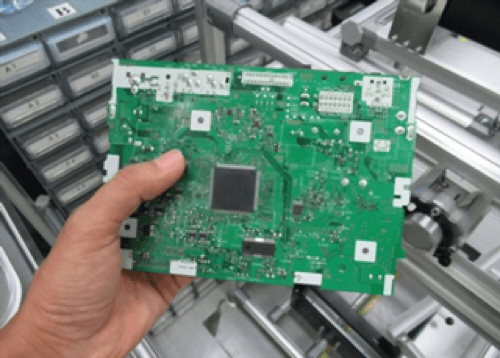

Even microscopic dust or other particles can ruin the product if it gets into the Printed Circuit Board (PCB) or other electronic components.

Likewise, excessive moisture on the parts can lead to failure or a short circuit. All this can be prevented with compressed air due to its low impact nature and high energy conversion efficiency.

Therefore, reliable air compressors have become vital for the electronic manufacturing industry to get work done efficiently and safely.

Do you need

Do you need

for your electronic components?

We have more than 30 years’ experience.

Application of Air Compressor In Electronics

Following are some of the prominent applications of air compressors in the electronic industry and electronic manufacturing:

- Printed Circuit Board (PCB) cleaning

Oil-Free Air Compressors are used for Printed Circuit Board (PCB) cleaning in industries as it is one of the non-obstructive, low impact, and non-abrasive ways.

It blows out the dust and other unwanted matter resting on the sensitive electronic components after production without leaving any oil contamination in liquid, aerosol, and vapor forms.

2 Pick and Place Machines

Pick-and-place equipment like robotic machines, also known as pneumatic robotic arms, used for component conveying, are powered with air-compressors to operate.

The controlled amount of compressed air from the air compressor is delivered to specific parts of the robotic machine via a tubing system. These parts convert the potential energy of the compressed air into mechanical energy to perform.

Air-compressor-powered pick-and-place equipment are preferred over electric, servo, and hydraulic powered systems in many applications as they are lightweight, robust, safe and less hazardous, precise, less expensive, easy to maintain, and work in extreme temperatures.

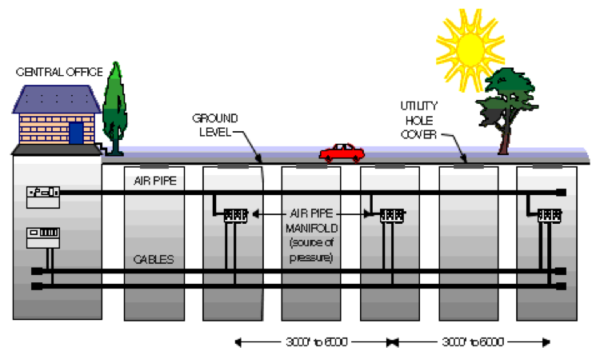

3 Cable Pressurization

Air compressors assist in maintaining a specific pressure in gas pipelines. The air pressure allows the natural gas to continue traveling along the pipeline to the intended recipient. Furthermore, air compressors are also used for testing and cleaning these pipelines.

Apart from gas pipelines, air compressors are also vital for maintaining underground telephone and TV cables. They keep the pressure within the cable higher than the force exerted to the outside of the protective sheath by standing water.

The standing water applies pressure on the underground cable (especially in storms), allowing water to permeate through the crack in the cable or splice case, causing electrolysis to occur, which results in faulted pairs within the cable.

Thus, the air pressure through the air compressor protects the cable from moisture damage by maintaining positive pressure within the cable. The Positive pressure exceeds and counters the external force caused by the water.

4 Surface Mounting Technology, Desoldering, and Test equipment

Air compressors are essential components for SMT (Surface Mount Technology) component placement systems, also known as pick-and-place machines.

These systems place the surface-mount devices (SMDs), including resistors, capacitors, and integrated circuits on PCBs (Printed Circuit Board), onto a printed circuit board (PCB).

The compressed air from the air compressor powers the SMT machine’s pneumatic parts, including the stop plate and splint mechanism. They also power plate support, suction nozzle changer, head pickup and placement, safety cover latches, pneumatic feeders, tubular feeders, and mobile feeders.

They are also used for desoldering and in test equipment during PCB production.

5 Telescopic antennas

Telescopic Antennas are used for Telecommunications, Broadcasting, Surveillance, Wind and Solar Energy Production, Disaster Recovery, Site Surveys, Site Security.

The telescopic antennas use air compressors to raise their central column to an extended height.

Moreover, air compressors are also used to de-ice mobile transmitters.

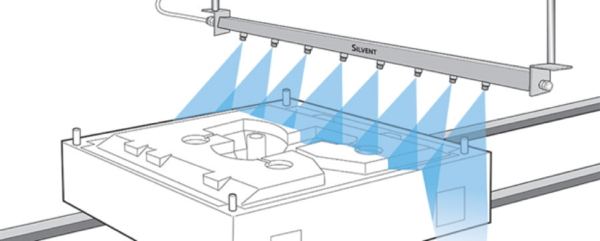

6 Air knives

Air Compressors powers the Air Knives tool. This tool blasts the compressed air on the material’s surface to remove or contain free-standing materials (solids or liquids).

During the production of printed circuit boards (PCB), the air knives remove solder paste and flux after conveyorized wash. Moreover, they are also used for drying bottles and cans after filling and rinsing, metals castings after automatic machining, etc.

7 3D Printers

Air compressors have a plethora of applications, including 3D printing.

3D printers need a controlled atmosphere with inert nitrogen, for which they convert clean and dry compressed air from oil-free screw air compressors to generate pure nitrogen using nitrogen generators.

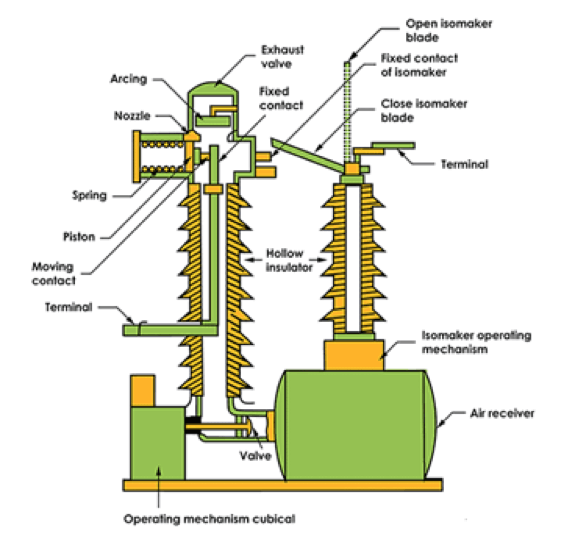

8 Hi-Voltage Pneumatic Circuit Breakers

An operating mechanism creates and stores the energy to operate a circuit breaker. Compressed air becomes the energy source for the Pneumatic operated mechanism for closing and tripping the hi-voltage circuit breakers. These pneumatic circuit breakers are called “Air Blast Circuit Breakers.”

The air compressor stores the compressed air in the storage tank (air receiver). When needed, it is blasted into the arc extinction chamber. This pushes away the moving contact. As a result, the connections are pulled apart, and the air blast moves the ionized gas away along with it and supports the arc extinction.

If you are associated with any of the above industries, you would likely need air compressors for your products. The problem you could face while buying is the quality and price of the air compressor. To solve your problem BENEAIR has a wide range of air compressors with good build quality and a reasonable price.

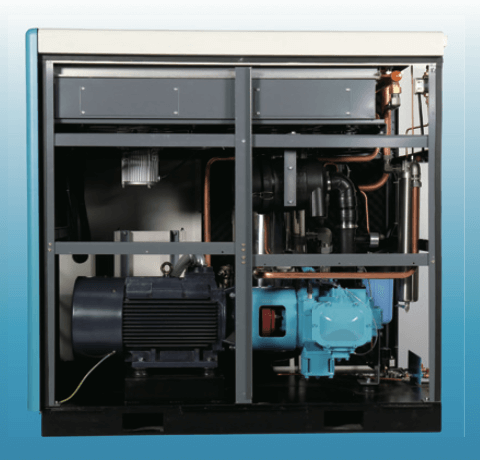

Common Equipment for the Electronic Applications

- If the compressed air will be applied to precision electronic industry, we suggest using 100% Oil-free type air compressor with the desiccant air dryer and filters.

- For a low-risk compressed air for production line, if with a limited budget, the oil-lubricated type air compressor with refrigeration air dryer and filters can be chosen, but for long term consideration, an oil-free type air compressor can not only produce high-quality oil-free and clean air but also costs lower for maintenance and energy.

Related Products

100% OIL-FREE

More than 20 years experiences in Water-lubricated Oil-free technology

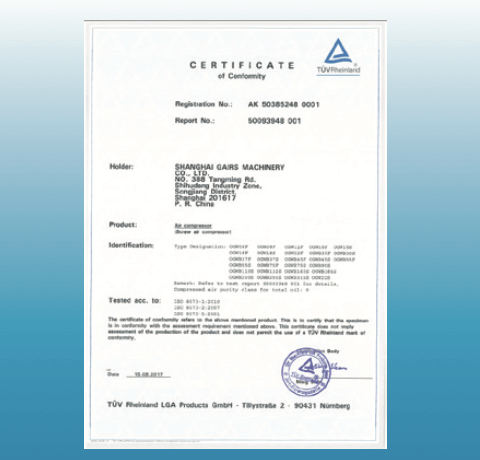

Germany Rhineland TUV Class 0 Oil-free Certification

RELIABLE

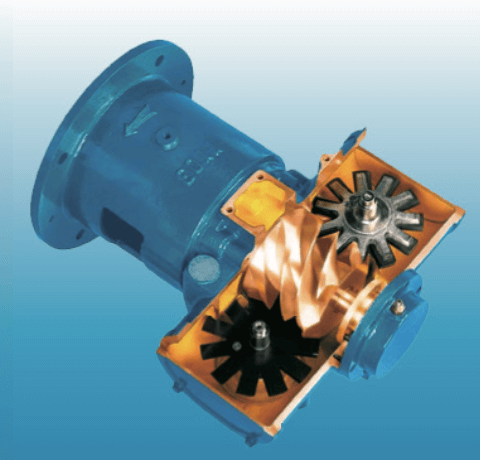

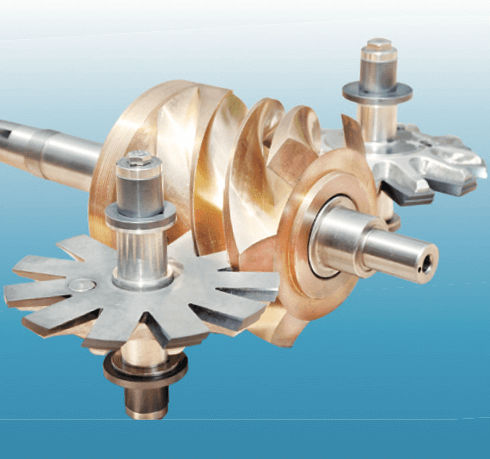

More than 30 years Single Screw Technology

Most balance and reliable structure

Low temperature(< 55℃) reduces the stress on components

LOWER MAINTENANCE

Without Oil Air Separation Unit

Consumable parts are only air and water filter elements

$100~$300/year

ENERGY SAVING>30%

Ideal isothermal compression and no heat waste(<55℃)

Most Advanced VSD and Two-stage compression technology

SUPER QUIET

Super dynamic balanced system

The motor and screw are directly connected

Sound absorbing materials are also used in the shell

AIR END

Optimal profile

Double stage energy saving more than 10% than single stage.

PM MOTOR

Direct Drive

Class 1 PM motor, Power factor: >95%, Oil-cooled type can be customized

VSD CONTROL

Automatic operation

Dynamic display all operation parameters, prevent accidents by the alarm.

EASY-MAINTENANCE

Patent technologies

Filters can be easy replaced in half an hour. Oil can be completely replaced.

OIL SYSTEM

Minimum pressure drop

Patent oil storage device can guarantee the oil supply of the air end after a long shutdown.

How to choose the right air compressor?

How to choose? Air-cooled or Water-cooled?

The cooling system works with lubricating oil/lubricating water and compressed air. The main purpose is to ensure

We replaced 21 piston type compressors with one 40bar 10cubic Screw type compressor.

No more noise, no more spare parts and high maintenance fee.

We began to use their oil free type products since 1998, the products are very reliable.

Their Water-lubricated Screw Air Compressor can ensure the 100% oil free and clean compressed air for our processing, and ensure the high quality of our products.

The oil free type screw air compressor energy saving 38.6% compared with our used air compressor, and saving 25.8% compared with the new oil lubricated type screw air compressors.

“Class 0 oil-free air compressor guarantee the best quality of our end products”

“Electrical costs and maintenance fee is significantly reduced.”