Contents

Compressed air is a valuable resource for many industrial and commercial applications. However, when not used efficiently, compressed air can be a major source of wasted energy. This article will discuss the best ways to dry compressed air to optimize its performance.

How to dry compressed air?

How to dry compressed air?

Drying compressed air is a process that uses either adsorption or desiccant drying. In both cases, dried compressed air costs less to produce and requires less cooling.

Adsorption:

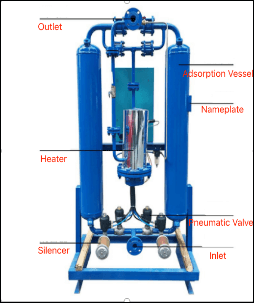

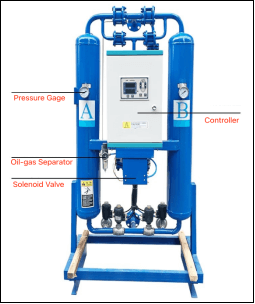

Adsorption dryers remove moisture using activated carbon, which draws the water in like a sponge. Adsorption dryers are low-cost and do not require much maintenance, but they can only dry air to a certain dew point.

For this reason, adsorption dryers are especially effective when temperatures are between 80°F and 95°F.

Desiccant:

Desiccant dryers all operate on the same principle: through a material like silica gel, they absorb moisture from the air. Desiccant dryers are more expensive to buy and maintain than adsorption dryers, but they can dry compressed air to much lower dew points.

Desiccant dryers break the bonds in water droplets using a material such as silica gel or calcium sulfate, and they can remove moisture from compressed air down to -38°F dew point with little effort.

They do this by adsorbing water molecules on a solid bed. Desiccant dryers are effective at lower temperatures, but they require more maintenance and have a shorter lifespan than adsorption dryers.

Best practices for removing moisture from compressed air

Best practices for removing moisture from compressed air

Draining Tank:

One of the simplest ways to reduce the amount of moisture in compressed air is to drain the tank regularly. This may be done manually or through an automated system.

The advantage of an automated system is that it can keep the tank drained even when the compressor is not running. This prevents moisture from accumulating in the tank and avoids the need for frequent draining.

Filtering:

Compressed air should be filtered before it is dried to remove any contaminants that may be present. A compressed air filter will remove the larger particles to keep them from clogging up the dryer.

After this stage, compressed air should be re-circulated through the system because it is not yet completely clean.

Refrigerant Drying:

If the compressed air is to be used in an application that requires low temperatures, then it can be dried with a refrigerant. This process uses cold coils to remove the moist from the compressed air.

Heat Removal:

Compressed air can also be dried by removing the heat from it. Heat removal dryers use a fan to blow cool air over the compressed air, which removes the moisture.

The downside of this method is that it takes up more space and consumes more energy than other methods.

Inline Drying:

Inline drying is a process that uses a heat exchanger to remove the moisture from compressed air. The heated compressed air is passed through a coil, where the moisture is condensed and removed.

The highest-capacity compressor is best for drying compressed air using this technique, but it also takes the most room.

Cooling:

Dried compressed air needs to be cooled again before it can be compressed. This is because low-pressure air has a much higher temperature than compressed air.

Cooling towers are used for this purpose, and they work using the same principle as refrigerant dryers. The compressed air passes through coils surrounding a tower filled with water, which cools the air via evaporation.

Over compression:

Compressing air beyond its saturation point will cause the water vapor to condense, so it is important to compression ratios to minimize the amount of moisture in the compressed air.

Using a dryer:

The best way to dry compressed air is by using a desiccant or adsorption dryer. These dryers remove moisture from the compressed air using a variety of methods, and they are available in both stationary and portable models.

To ensure that compressed air is as dry as possible when it goes from one facility to another, a centralized system with high-efficiency compressors should be used. This way dried compressed air can be distributed throughout a facility quickly and efficiently.

The best practices for drying compressed air should be followed not only to improve the quality of compressed air but also to reduce energy costs and improve profits. By following these steps, you can maximize the amount of time that your compressors are producing high-quality dried compressed air.

Why is it necessary to remove contaminants?

Why is it necessary to remove contaminants?

- Industrial processes use compressed air to power tools, and machines, the quality of the compressed air has a significant influence on the finished product. In some cases, compressed air is used as a power source for tasks such as cutting or grinding, so it is important to remove any contaminants from this form of energy to protect workers and ensure sharp metal edges.

- Peat moss can produce dust particles that are harmful when inhaled, so compressed air should be filtered before it is sent into a ventilation system.

- When compressed air is required for medical equipment, contaminants can also cause problems. Dirty compressed air can damage sensitive medical equipment and cause poor patient outcomes, so it must be filtered to remove any harmful particles.

- Humid conditions are the perfect environment for bacteria to grow, which means that humid environments should not be used where sterile conditions are required. Clean compressed air eliminates this risk by preventing the growth of harmful microbes in applications such as food processing plants and hospitals.

- Using too much nitrogen in a mixture with oxygen can lead to an explosion, so it is important to maintain the right balance between these two gases. When adding nitrogen for safety reasons, it needs to be done in the proper ratio by volume to avoid this risk.

Drying compressed air can be an effective way to minimize wastewater production and reduce energy costs for industrial facilities. There are several different methods available for drying compressed air, no matter what type of application needs it.

The best method depends on the specific needs of each facility, so it is important to discuss various options with manufacturers in order not to waste resources or equipment downtime due to poor choices between suitable solutions for each customer.

Leave A Comment