Why is an Air Dryer Required?

An air dryer is essential for all air compressors regardless of it being used in an industrial or residential area. The condensation forming in your air compressor can negatively impact your compared air line network, machine, and tools. It is essential to protect your production.

If an air dryer is not used in an air compressor, it can have the following impact on your production:

- Could start corrosion in boilers and pipes

- Infect the oil and lubricants in pneumatic tools

- Cause blocking and fog in surfaces that are sprayed with compressed air

An air dryer in air compressors removes unwanted vapors and moisture from the air compressor mitigating the risk of the product being contaminated and the machines getting corrosive and rusted.

An operating mechanism creates and stores the energy to operate a circuit breaker. Compressed air becomes the energy source for the Pneumatic operated mechanism for closing and tripping the hi-voltage circuit breakers. These pneumatic circuit breakers are called “Air Blast Circuit Breakers.”

The air compressor stores the compressed air in the storage tank (air receiver). When needed, it is blasted into the arc extinction chamber. This pushes away the moving contact. As a result, the connections are pulled apart, and the air blast moves the ionized gas away along with it and supports the arc extinction.

Functions of an Air Dryer

An air dryer is designed to minimize the number of water particles and moisture. Its function in an air compressor is to create a dry and clean environment for smooth and effective working. If an air compressor contains vapors and moisture, it will draw into the machine and create a harmful liquid that would result in contamination of the product. It can also cause frozen pipes and lead to corrosion and other issues.

An air dryer would help keep the inside of an air compressor dry. It reduces the vapors in the compressed air via cold generated adsorption drying inside which the compressed air passes through granulates. It also reduces the dew point at the same time.

Selection Criteria of an Air Dryer

The requirement of an air dryer varies as per the scope of the work. With the rapid technological enhancements, air compressors and dryer systems are becoming more effective and efficient. It is essential to understand the criteria on which to decide what kind of air dryer you require for your system.

Whilst choosing an air dryer, it is vital to keep the maximum capacity of your system in consideration. The capacity of a system is determined In SCFM at 100 PSIG. The capacity can be estimated by multiplying the horsepower of the air compressor by four.

The requirement for an air dryer highly depends on the maximum and minimum operating pressure of your system. A dryer is rated at 100 PSIG, and for every increase in 100 PSIG, the capacity of the system decreases. The lesser the pressure, the less moisture load, and thus reduces the strain on the compression system.

-

Air Inlet and Dew Point Pressure

The minimum and maximum operating inlet temperature and the dew point pressure of an air dryer should be significantly considered while choosing an air dryer. An effective air dryer will work below the lowest ambient temperature to which the air compressor might be vulnerable. Keep in mind the dew point of the system. You can calculate it by reducing the lowest air temperature by 20 degrees.

It is vital to recognize if you need a high-temperature or a low-temperature dryer by determining the minimum and maximum operating ambient air temperature of your system. Ambient temperature over 200 Fahrenheit would exceed the maximum inlet temperature. High-temperature driers can survive a higher ambient temperature during summers. As per the guidelines, the ideal pressure dew point should be lower than the lowermost ambient temperature in the facility, or else the moisture will condense in the airlines causing inefficiency and disturbance.

-

Application and Environment

It is essential to consider the air usage whilst choosing an air dryer for your system. This would help you understand if you need a refrigerated dryer or a desiccant dryer for your system. A refrigerated dryer can produce air with 10-20 relative humidity whilst a desiccant dryer can produce less than 0.5% relative humidity.

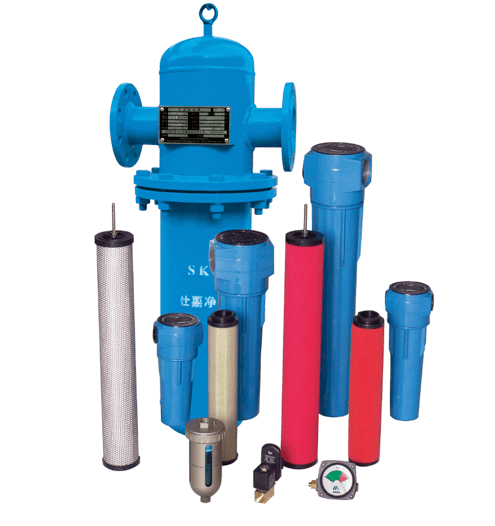

Types of Air Dryers for Air Compressor

One type of air dryer doesn’t fit all. Various types of air dryers are used in different situations like for industrial or non-industrial use.

Here are a few of the commonly used air dryers;

A refrigerated dryer is the most popular type of dryer used widely. A refrigerated air dryer ensures a cooling process that is employed to prevent moisture in the air compressor. Similar to a kitchen refrigerator that cools and saves delicate food items, a refrigerated air dryer retains the quality of air in manufacturing plants.

A refrigerated air dryer cools the air compressor up to 35 degrees Fahrenheit. It passes in the air compressor inlet valve, dries and extracts the moisture and the newly dried air is reheated by incoming air. By the end of the cycle, the compressed air has a dew point of 35 to 40 degrees Fahrenheit. These air dryers are generally inexpensive to install compared to others and have a lower maintenance cost.

A Desiccant air dryer comprises two towers – one for drying and one for regenerating the desiccant. The drying tower consists of a porous desiccant material that obstructs vapors and moisture as compressed air through the inlet.

A single tower desiccant air dryer consists of a single desiccant that is used to dry air coming from the environment. These dryers don’t require electricity to operate. They are preferred in dangerous and corrosive environments. There are further three types of desiccant air dryers – heated, heatless, and heat of compression.

Chemical air dryers contain a chemical inside that is used to extract moisture from compressed air. These chemicals have the natural capacity of water extraction like sodium, calcium chloride, and lithium. These chemicals absorb all the vapors and water particles in the air and are later disposed of with the water they collected. Chemical air dryers have high-quality filtration systems used for water extraction. Otherwise, these chemicals will build up in the air compressors and will cause disturbances and performance problems.

Chemical air dryers are easy and reliable, therefore they require very little ongoing monitoring. They have no moving parts to maintain and are relatively inexpensive to install and set up. Although, replacing high-quality chemicals and filters can be a little expensive. Disposal of the chemicals containing the extracted water can be a little challenging and tricky.

Membrane air dryers are used for dehumidification and for applications that entail gas separation like food production. Compressed air enters the membrane dryer and moves across bundles of semi-permeable membrane filters that allow only certain materials, for instance, oxygen to go through the membrane. It separates these materials from the desired gas.

A membrane dryer doesn’t require electricity that makes them perfect for remote operations. On the other hand, they make the least noise so people prefer them. They are easy and inexpensive to maintain. Although, membrane air dryers need consistent air, free of oil, and particulate. The changing of their filters is consistent and requires attention to mitigate the risk of blockage.

What is Pressure Dew Point?

Understanding the definition of a pressure dew point is necessary to understand the working of an air dryer. Pressure Dew Point (PDP) is the amount of water content in an air compressor. It is the temperature at which water vapor changes into the water at the contemporary working pressure.

Every dryer has a different PDP. For instance, the pressure dew point of +2 degree Celsius at 7 bar is equal to -23 degree Celsius at atmospheric pressure. In this situation, using a filter to remove moisture would never work since further cooling at this point will lead to continued precipitation of the water.

Working Process of an Air Dryer

An air dryer is highly essential for an air compressor to ensure it stays dry from the inside in order to keep the product and the compressor safe and mitigate the risk of corrosion. The working of an air dryer can be a little tricky.

The dryer is connected to both refrigerated and absorption dryers equipped together. The air that deals with the refrigerated dryer is supposed to directly enter the absorption dryer through the air and water separator. At this point, the air temperature will be around 2 degrees Celsius to 5 degrees Celsius and the dew point is approximately 5 degrees Celsius.

The air will now enter the absorption dryer and will profoundly be absorbed. The lower the dew point at this time, the better. At this point, the part of the water has already been cleaned up by the refrigerated dryer before it enters the absorption dryer. This would lessen the working of an absorption dryer therefore it can withstand a long time in shift, then decrease the air consumption.

Air dryers are used for both industrial and residential use. Although, it is more widely used for industrial purposes. Here are a few usages of air dryers in the industrial areas.

In the medical field, air dryers are widely used for applications like bone screws, stents, and medical transplants like scrubbing medical molding, etc.

Air dryers are essential for space science applications like cleaning orifices in turbine blades, eliminating magnesium oxide insulators from thermocouple harnesses, carving optical lenses, and other usages.

Air dryers are used in the heavy industry for day-to-day activities like finishing and texturing injection mold cavities, recasting and discoloration, cleaning runner nozzles, and a lot more.

Air dryers are used for the cleaning, cutting, coloration, and preparation of semi-precious stones and other kinds of jewelry.

On the other hand, air dryers are used in most activities in the non-industrial/ residential areas like spin dryers, hairdryers, condense dryers, heat pumps dryers, dryers used in washing machines, or dishwashers. They are basically used for all purposes in a household where drying is necessary.

Disposal of the Condensate After Air Drying

People who run the compressed air system need to understand the process of proper disposal of the condensate, considering the environmental laws. It is essential to know that the condensate consists of tiny particles of oil that is not visible to the human eye and therefore needs proper disposal as to not harm the environment

Now, you will be able to see the condensate at the back of your compressors and dryers. These condensates are piped to an ongoing oil and water separator that leads to a foul drain. If the condensate is falling off directly to the ground or a plastic bag then you should be highly concerned. You should install an oil/water separator in order to ensure proper disposal.

On this note, there are different rules and regulations of disposal in different regions. So before setting up a procedure of disposal, consider the rules and regulations of disposal in your country.