Air Compressor for Glass Industry

An air compressor is used widely in several industries all around the world. The function of an air compressor is to convert power into potential energy and store it in pressurized air.

An air compressor is one of the most significant mediums in the glass industry. It is used for many purposes. It is used in workshop activities like production lines and raw material lines. The main purpose of an air compressor in the glass industry is for combustion, medium transportation, instrument operation, source of air for equipment, and more.

Do you need

Do you need

We have more than 30 years’ experience.

Applications of Air Compressor in Glass Industry

Combustion

An air compressor is mainly used to assist the glass liquid combustion in the melting furnace for production. It is used to atomize the medium to achieve maximum combustion and to eliminate the residues in the idle oil. This protects the cavity from cooling throughout the fire-altering process.

Medium Transport

Air compressor is used to transport and spray coke powder in the pipelines. For instance, the ultrafine powder is collected and conveyed from workshop to workshop through pipelines in order to achieve a more reliable and fast speed and reduced transportation cost. It also mitigates the impact of ultrafine dust diffusion on the environment whilst transport.

Equipment Implementation Gas

Air compressor is a part of several pneumatic types of equipment in the glass industry including operating air source, ball valve operating air source, and other equipment like cameras, lens cooling, etc.

Environmental Dust Removal System

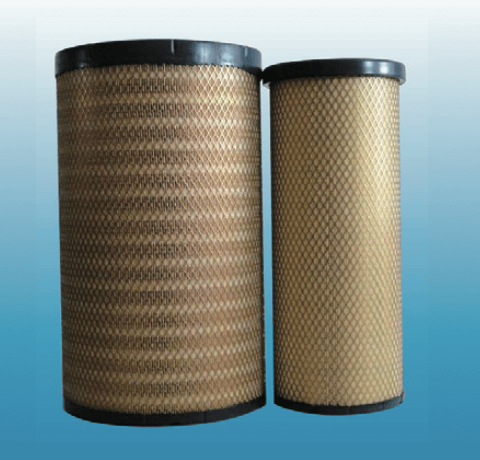

An air compressor is vital for the back blowing of a filter barrel – dust collection equipment. This can include a dust collector, self-cleaning air filter, etc. it is used in a semi-dry desulfurization system in order to filter the particles from the air.

Bottle Blowing

Molten glass is given shape with the help of an air compressor. The air is blown on the glasses with high pressure during the molding process and given a shape. Although, both need compressed air provided by an air compressor which is then filtered and dried.

Air Compressor Issues in Glass Industry

Air compressors play a significant role in the glass industry. Although, these air compressors have some common issues faced from day to day in the industry. Some of the common issues include:

- Poor efficiency of centrifugal compressors.

- Poor efficiency – this usually happens due to inaccurate configuration of the control system.

- High inlet temperature – this is impacted by the location of the compressor house.

- Old pipework – this happens with the increase of add-ons over time.

- Leakages in the production instruments.

- Waste of compressed air during maintenance processes.

- Misapplication of air compressors

Compressed Air in the Process of Glass Manufacturing

Compressed air plays a significant role in the manufacturing of glass and is used in several steps.

-

The Ingredients

The manufacturing of glass needs a lot of ingredients including sand, limestone, and soda ash. The raw materials are mixed and funneled in several chambers in hot temperatures to mix them properly. An air compressor is used to convey the mixture accurately from one chamber to another. This process takes approximately three days.

-

The Melting Stage

The melting stage takes about ten hours of the raw material in the burning furnace. At this step, an air compressor is significant to ensure the mixture remains intact and in the furnace. It ensures proper rendering.

-

Shaping

At this stage, the raw materials are given a shape of a container with the help of an air compressor. These containers are then layered with thin tin in order to give them the perfect finishing.

-

The Cool-Down

During the cool-down process, the compressed air lowers the temperature to a level that makes it easy to render the glass. A glass production plant can power pneumatic blowers for maximum speed and efficiency with the help of a rotary air compressor.

-

Cutting

The glass is cut into smaller pieces – these pieces are lifted with a conveyor belt with the help of pneumatic suction arms. These glasses are then used for windows and doors etc. and are given further designs as per the requirements.

Common Equipment for the Glass Applications

Demands placed in the glass industry are rising by the day. With scale application, air compressors help in blending, pneumatic actuators, conveying material molding, cooling, glass blowing, shaping, and a lot more.

For bottle making or sheet-glass production, air compressors play a significant role in every step. From moving the raw material in the chambers to giving it a perfect shape – air compressors are needed in the procedure. The air compressors used in the glass industry are highly important and need constant maintenance. It is required to keep the compressors up to date and well-structured.

- If the compressed air will be applied to the glass industry, we suggest using a 100% Oil-free type air compressor with an air dryer and filters.

- If with a limited budget, the oil-lubricated type air compressor with refrigeration air dryer and filters can be chosen, but for long-term consideration, an oil-free type air compressor can not only produce high-quality oil-free and clean air but also costs lower for maintenance and energy.

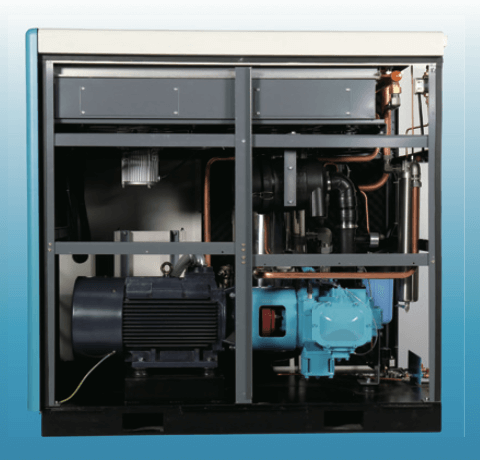

Related Products

100% OIL-FREE

More than 20 years experiences in Water-lubricated Oil-free technology

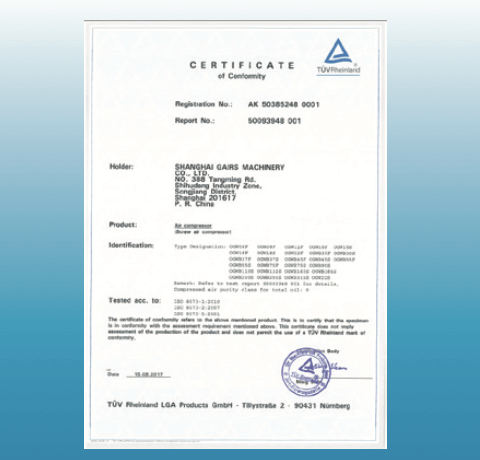

Germany Rhineland TUV Class 0 Oil-free Certification

RELIABLE

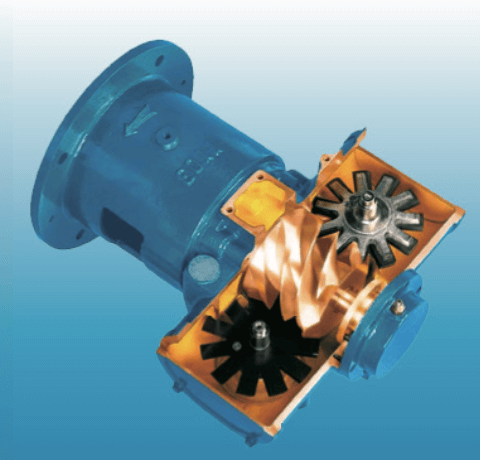

More than 30 years Single Screw Technology

Most balance and reliable structure

Low temperature(< 55℃) reduces the stress on components

LOWER MAINTENANCE

Without Oil Air Separation Unit

Consumable parts are only air and water filter elements

$100~$300/year

ENERGY SAVING>30%

Ideal isothermal compression and no heat waste(<55℃)

Most Advanced VSD and Two-stage compression technology

SUPER QUIET

Super dynamic balanced system

The motor and screw are directly connected

Sound absorbing materials are also used in the shell

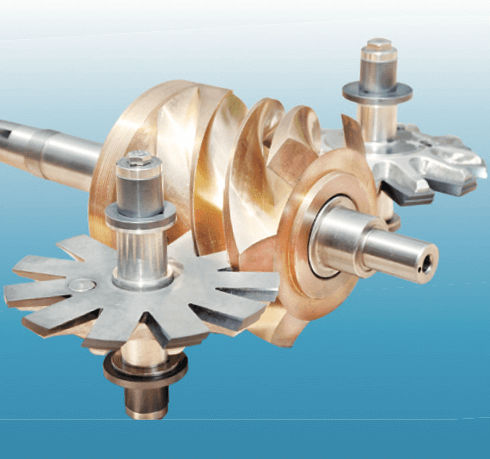

AIR END

Optimal profile

Double stage energy saving more than 10% than single stage.

PM MOTOR

Direct Drive

Class 1 PM motor, Power factor: >95%, Oil-cooled type can be customized

VSD CONTROL

Automatic operation

Dynamic display all operation parameters, prevent accidents by the alarm.

EASY-MAINTENANCE

Patent technologies

Filters can be easy replaced in half an hour. Oil can be completely replaced.

OIL SYSTEM

Minimum pressure drop

Patent oil storage device can guarantee the oil supply of the air end after a long shutdown.

How to choose the right air compressor?

Air Compressor Sizing

Whether you're starting your business or adding a new compressor to your setup, you need to choose the

Meeting Standards for Compressed air for Electrical Bus or Railway

You may not be aware of the fact that your everyday smooth railroad venture exclusively relies upon

What Is Ambient Pressure and Why Is It Important?

Many screw-type air compressors have an adjustable regulator screw. This screw controls the pressure of the compressed air

What to Look for in a Dental Air Compressor?

A dental compressor is a device that provides compressed air to any equipment requiring compressed gasses. It supplies

Air Compressor Horse Power

Most people assume that all air compressors are the same; however, this is not true. The horsepower of

Air-Cooled vs. Water-Cooled Compressor

In the procedure of compression of gases, the air compressor creates a lot of heat. The air compressors

We replaced 21 piston type compressors with one 40bar 10cubic Screw type compressor.

No more noise, no more spare parts and high maintenance fee.

We began to use their oil free type products since 1998, the products are very reliable.

Their Water-lubricated Screw Air Compressor can ensure the 100% oil free and clean compressed air for our processing, and ensure the high quality of our products.

The oil free type screw air compressor energy saving 38.6% compared with our used air compressor, and saving 25.8% compared with the new oil lubricated type screw air compressors.

“Class 0 oil-free air compressor guarantee the best quality of our end products”

“Electrical costs and maintenance fee is significantly reduced.”