Contents

The air compressor generates a lot of heat in the process of compressing the gas, there are several ways to cool the air compressor:

- Air-cooled Compressor

- Water-cooled compressor

- Open systems without circulating water (connected to an external water supply)

- Open systems with circulating water (cooling tower)

- Closed systems with circulating water (including an external heat exchanger/ radiator)

Working principle

Working principle

Air-cooled compressor

The method used by an air-cooled compressor is that it uses air to decrease the temperature of the air that is in compressed form and of material of any sort if present. When heat is generated by a compressor, the temperature of hot air is reduced by an air-cooled circuit that comes along with a radiator and a fan. Nowadays, an air-cooled compressor is considered the most common air compressor cooling system. Thus, it is more approachable than any other water-cooled system.

The heat loss for an air-cooled compressor can be recovered by the industries in a unique way. It is done by utilizing the energy to heat several buildings or a preheating battery can be powered as well. In this way, a huge sum of money is saved. The heat is directed via a special circuit towards an area that has a fan. However, in cases where excess heat is produced, that is not required, then the hot air is directly released into the surrounding atmosphere with the help of an air damper control or a thermostat could also be helpful.

Water-cooled compressor

The method employed by a typical Water-cooled compressor is that it uses a liquid lubricant or coolant which comes from a unit that is external and thus during the method of compression, it cools down the compressed gas as well as material of any sort if present. Just like the air-cooled compressor, it also includes a circuit, but the circuit here differs because it decreases the heat with a tube and shell exchanger. These units are more commonly utilized in those machines that have the high-powered horsepower.

The water is reused on a large-scale company as they use it in many water heating systems. The heated water is used for cleaning, showering, or washing. Companies can reuse the water from the compressor in a hot water heating system, usually for bathing, washing, or cleaning. A water-cooled screw compressor may allow a business to invest in a smaller water boiler because you won’t need as much hot water.

Precondition

Precondition

Any water-cooled screw compressor, in order to function properly, would need high-quality cooling water. If the water is obtained from a water body such as from an ocean, well or river, lake, or well, then a cooling tower must also be installed. Along with it, a closed-loop system is also needed as it filters the water and boosts the lifespan of your system.

If your building already does not have this facility then it is going to put a burden on your budget. Apart from its purchase, you will have to install the system of machinery as well as keep a focus on its maintenance, thus it can be a bit costly. In case, you already have a cooling system that is a closed-loop cooling system on-site, you will have to make sure that it is capable of accommodating the water-cooled compressor before its installment.

On the contrary, what an air-cooled screw compressor requires is sufficient space and cooling air so that there is a provision of enough airflow. The programming and planning must be very thorough as if not, then it might arise some technical issues and it might result in improper regulation of temperature of commercial facilities. Make sure that the compressor room is not too hot. If the temperature of the compressor room is not maintained, then it can result in faulty devices and shutdowns that are uncalled for.

In order to protect your apparatus to ensure that workflow is not discontinuous, you must place a channel from each side of your compressor so that free air is permitted to move all around the given area. During cold weather, the heat from the apertures can be used to heat up the commercial premises. You must consider setting up a water cooled compressor if the business of yours does not afford a sufficient space for an extra apparatus.

Energy recovery methods

Energy recovery methods

Most of the time, the recovered energy is in the form of heat, but occasionally it might not occur. If the compressor offers a load that varies or is variable, then the amount of energy that is recovered will not remain constant. Thus, if we want the recovered energy to be beneficial, we need to make sure that the provided heat energy is constant and not variable. The air-cooled compressors work in a way that they undergo a production of hot air flow at a higher rate while keeping the temperature low. In this way, the energy becomes reusable to heat up the buildings.

Sometimes, an enormous amount of heat energy is generated that exceeds the demand of the building. That heat energy is then released in the atmosphere. It can be done automatically or manually. The factor that can play a role in limiting the recovery of heat energy is the gap between the main building, that we need to warm up, and the place where a compressor is installed. Try to keep this gap as narrow as possible. Moreover, the recovery is also provided with hindrance in winters, when the temperature drops down tremendously.

The cooling water from a water-cooled compressor provides cool water with a 90 degree temperature and it can help in augmentation of a heating equipment system with hot water. Even if hot water is serving the purpose of bathing and cleaning, what you still need is a water boiler that has a proper base load. The recovered energy from the compressor is useful as it reduces the expenses of fuel. The degree of energy recovery depends upon the compressor type with which we are dealing the easiest compressors that are modified and used to recover energy are oil-free compressors. When we consider the oil lubricated compressors, the oil is the basic factor in these compressors, as so indicated by the name of the compressor. However, this very basic component that is the oil becomes a hindrance in the recovery of energy.

Application

Air-cooled compressor

- It is used to heat up the buildings.

- Any preheating battery can be charged by it

- They produce compressed air which is used for gas cylinder filling.

- To empower tools such as jackhammers.

Water-cooled compressor

- It is used where a plenty amount of water is present.

- Thus, it can be installed near a water body like a lake or a river.

- It is also used to warm up the buildings.

Difference between air-cooled compressors and water-cooled compressors

Difference between air-cooled compressors and water-cooled compressors

- Expenditure of energy: As compared to water-cooled compressors, the air-cooled compressors need more energy and power.

- Cost of electricity: If you want to save money, then a water-cooled compressor is definitely not a good idea. They are very costly as they require not only water but also electricity and other treatment expenses. Thus, if you want to keep it low on your pocket, then proceed with an installment of an air-cooled compressor.

- Recovery of resources: in terms of recovery of resources, both of these compressors make sure to provide the resources that can be used again. Thus, it offers compensation in terms of charges and expenses. In order to reuse the water of a water-cooled compressor, you can preheat the boilers in winters, thus saving on the heavy gas and electricity bill. The warm air from an air-cooled compressor can be used to make your homes warm and cozy and it can also be used to ignite a fluid heat exchanger.

Advantages |

Disadvantages |

|

|---|---|---|

| Air-cooled |

|

|

| Water-cooled |

|

|

Maintenance

Maintenance

Everything requires regular maintenance to function properly. Since air cooled compressors are equipment of special type, it is a must to monitor the condition and function of your device. You also need to replace the fittings of compressors from time to time. All of this is done to make sure that the compressors function properly and have a longer life span.

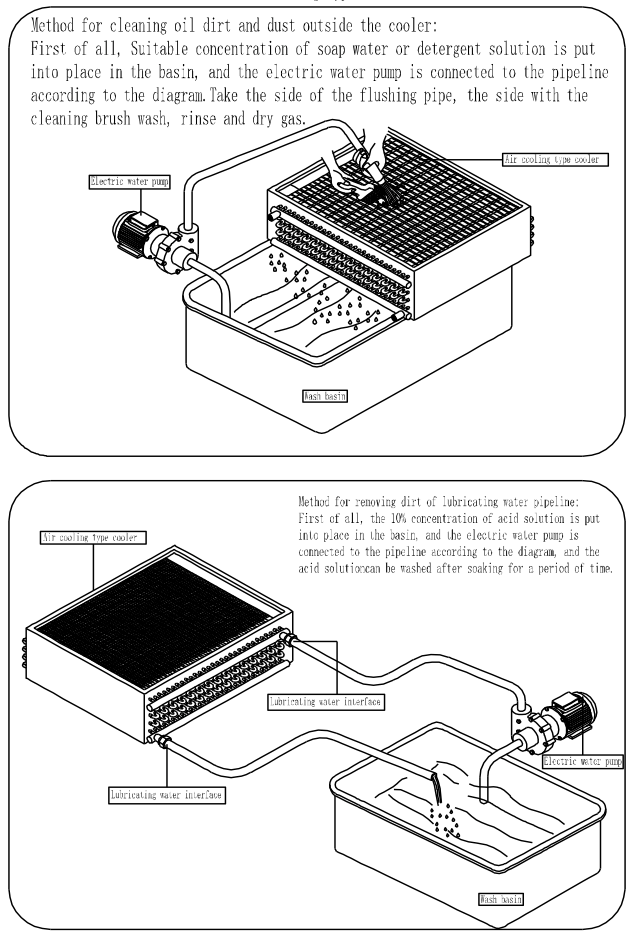

Maintenance method for Air-cooled cooler of air compressor

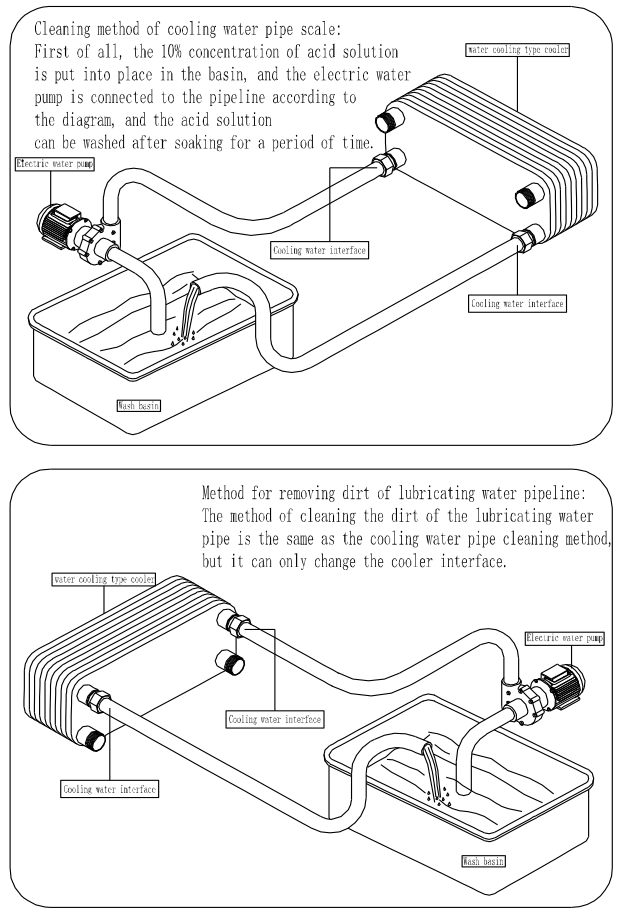

Maintenance method for Water-cooled cooler of air compressor

Leave A Comment