Dental Air Compressor

For dental clinics, hospitals and labs, an air compressor is a vital part that must be reliable and will be used everyday. So what we need is a low-noise 100% oil-free type air compressor to keep instruments clean and our patients safe during dental procedures.

Clean compressed air most widely used for cleaning, drying process, and powering tools. Typical applications are Dental milling machines, Autoclaves, Sterilizing, Patient simulators, ENT air/vacuum aspirators, Respiratory Equipment, Oxygen concentrators, Nebulizers, Surgical instruments, Tire inflating of wheelchair tire.

Do you need

Class 0 Oil-free compressed air

for your Dental Chairs and tools?

Do you need

for your Dental Applications?

We have more than 30 years’ experience.

How to Choose The Right Dental Air Compressor

When choosing an air compressor for dental practice, the following factors should be pay attention to:

Pressure

Evaluate and confirm all the air pressure requirements of your dental tools, the pressure you choose should be higher than your maximum air pressure needs. We should take the pressure loss/pressure drop into account. Most dental applications need about 5~6bar pressure, and choose a 7~8bar air compressor.

If the air pressure of the air compressor is lower than the requirements of your tools, may cause damage to the tools and harm to your patients. For example, lower pressure reduce the capacity and failing to drill or cut takes longer time to treat your patients, which costs more time and lets your patients feel bad.

Air Flow

Just like the air pressure, evaluate and confirm all the air flow or air capacity requirements of your dental tools, the air flow you choose should be higher than the total air air flow you need. As a rule of thumb, each dental chair needs about 50 l/min (50LPM OR 2CFM) @ 6 bar, to meet the HTM 2022 standard. You should account for the number of chairs that will be used at the same time.

Power

Most dental clinics need 1~5hp oil free air compressor to run the dental tools, but for some big dental hospitals, the power will be higher.

Related Products

Quality Requirements for Dental Compressor

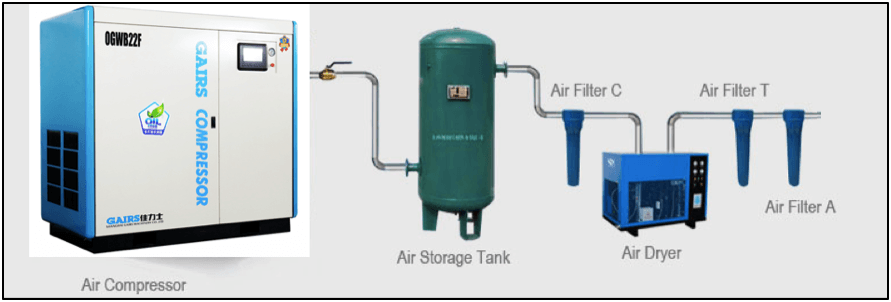

In the dental industry, the compressed air should be purified of contaminants before use.

General contaminants are solid particulates, water vapor, and moisture, oil vapors. Which are in the atmospheric air, the lubricating oil for oil-injected type air compressor, the pipes, storage air tank, and distribution.

High quality compressed air is safer for your patients.

Remove the moisture

Generally, for the dentist compressed air, the dew point should be -20℃~-40℃ and use a desiccant air dryer, and for low-risk non-contact compressed air, the dew point can be 3℃ and use a refrigeration air dryer.

Remove the oil

The oil exists in the atmospheric air, so even you choose a 100% Oil-free type air compressor, there is still oil vapor in the compressed air, so the filters should be used. Generally, for dental compressed air, use a 100% oil-free type air compressor is a must.

Remove the particles

The atmospheric air includes solid particulates or dust that may cause contamination if contact with the food products. Other contaminants may come from internal mechanisms of the air compressor system. We also need to use filters to ensure the particle content is no more than 0.01μm.

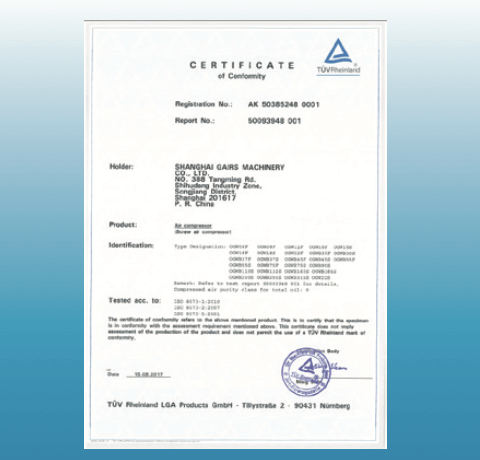

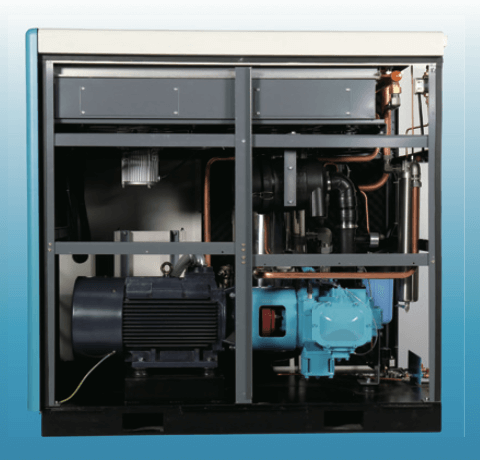

100% OIL-FREE

More than 20 years experiences in Water-lubricated Oil-free technology

Germany Rhineland TUV Class 0 Oil-free Certification

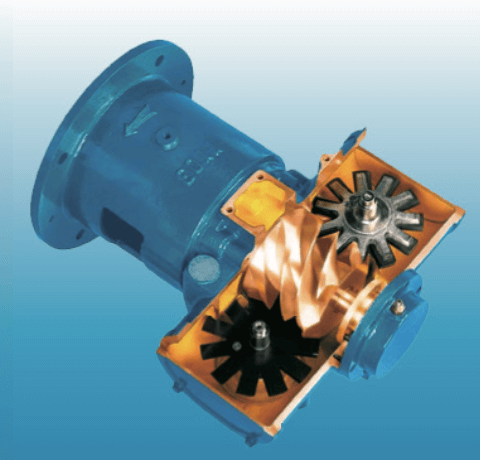

RELIABLE

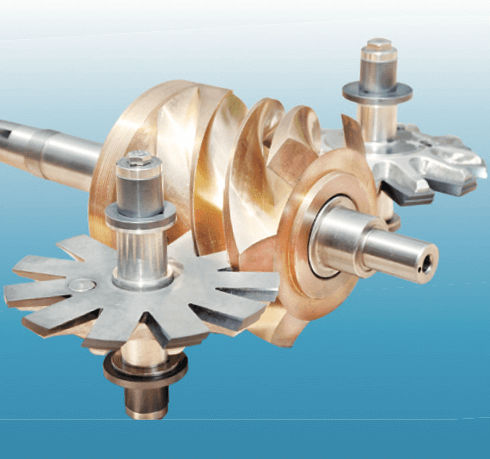

More than 30 years Single Screw Technology

Most balance and reliable structure

Low temperature(< 55℃) reduces the stress on components

LOWER MAINTENANCE

Without Oil Air Separation Unit

Consumable parts are only air and water filter elements

$100~$300/year

ENERGY SAVING>30%

Ideal isothermal compression and no heat waste(<55℃)

Most Advanced VSD and Two-stage compression technology

SUPER QUIET

Super dynamic balanced system

The motor and screw are directly connected

Sound absorbing materials are also used in the shell

How to choose the right air compressor?

Screw VS Piston Air Compressor

In recent years, screw air compressors have gradually replaced piston type air compressors. They become the mainstream

What Compressor Size do I Need?

An appropriate selection is beneficial to both the end-user and the compressor equipment. A too-large selection is

Some questions to ask yourself before buying an air compressor

For buying an air compressor, how to choose the right one for your industry? you should ask yourself

The relationship between air compressor pressure, flow and power

With constant power, when the rotation speed changes, the flow and pressure also change.

Should I choose the VSD air compressor?

The VSD(Variable Speed Drive) air compressor uses the variable frequency inverter compared with the regular Fixed speed

What Cooling method should I choose?

For most small models, it is better to use the air cooling type air compressor. There are

We replaced 21 piston type compressors with one 40bar 10cubic Screw type compressor.

No more noise, no more spare parts and high maintenance fee.

We began to use their oil free type products since 1998, the products are very reliable.

Their Water-lubricated Screw Air Compressor can ensure the 100% oil free and clean compressed air for our processing, and ensure the high quality of our products.

The oil free type screw air compressor energy saving 38.6% compared with our used air compressor, and saving 25.8% compared with the new oil lubricated type screw air compressors.

“Class 0 oil-free air compressor guarantee the best quality of our end products”

“Electrical costs and maintenance fee is significantly reduced.”