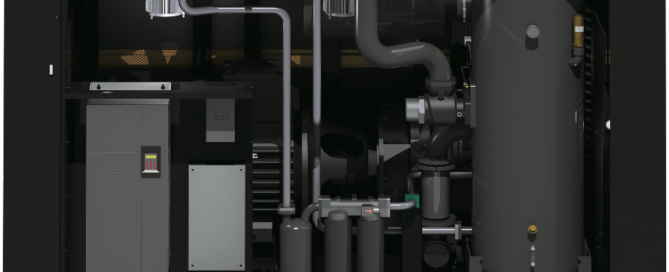

How to save air compressor maintenance costs?

How to maximize corporate interests? In addition to increasing income, you also need to control the costs. One of the necessary expenditures for air compressors is maintenance costs. How to reduce maintenance costs? Some strategies for your reference. 1. Renewal and technical transformation of air compressors At present, there