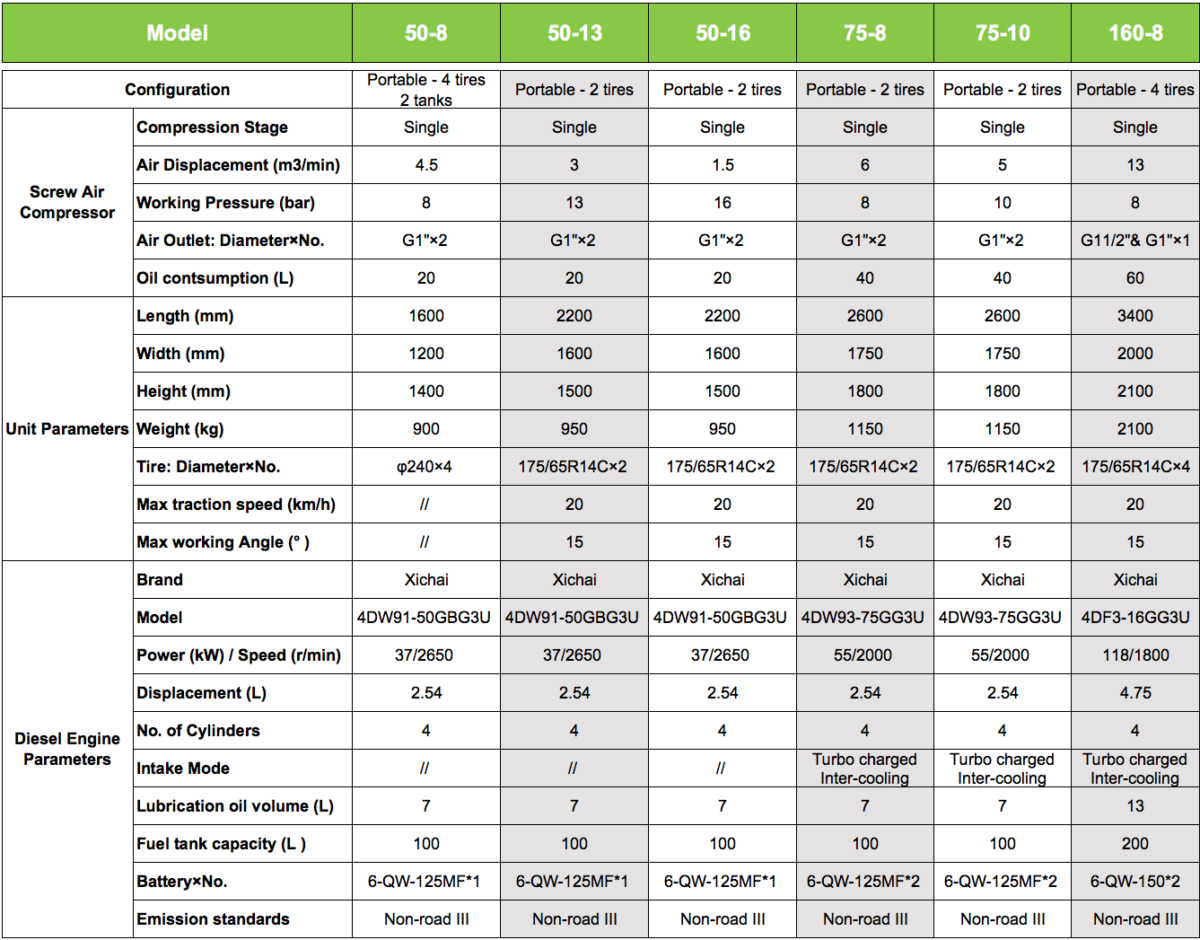

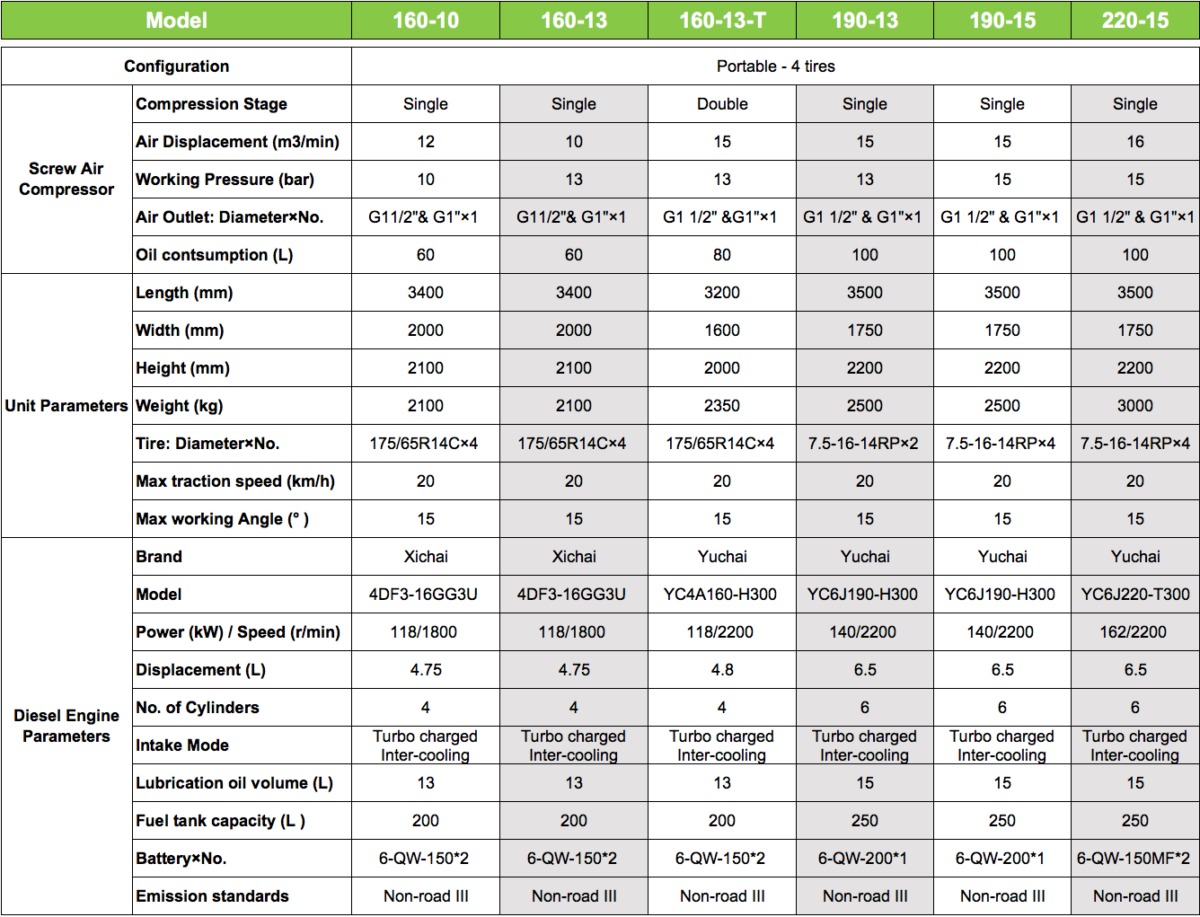

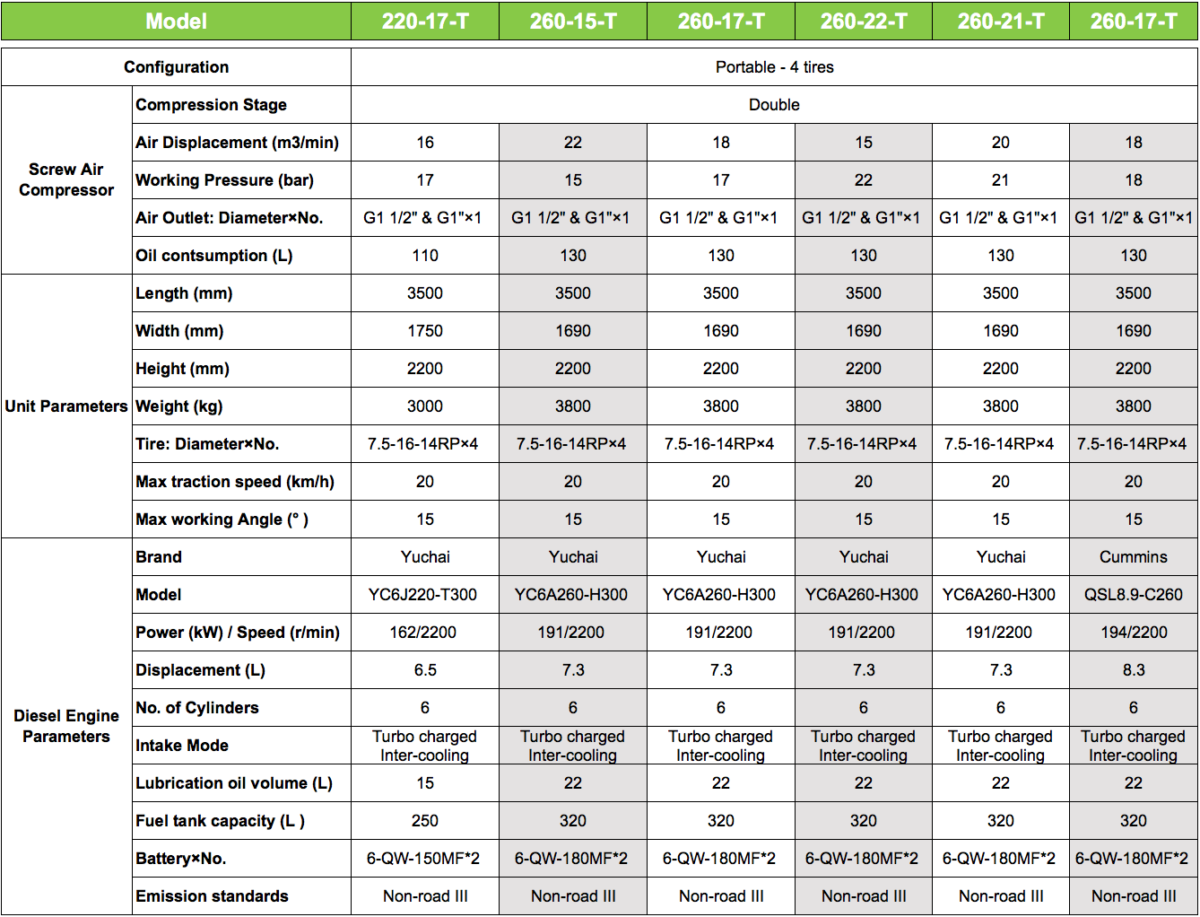

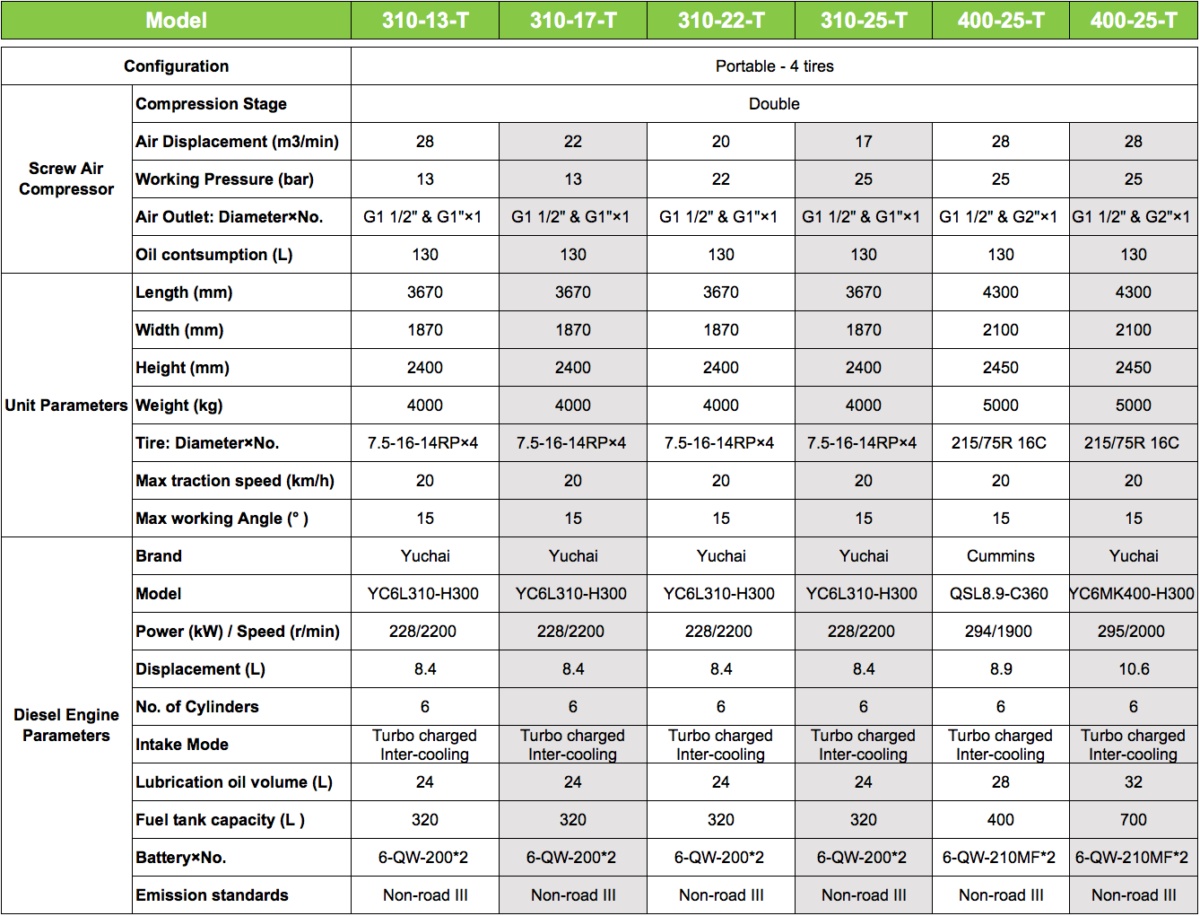

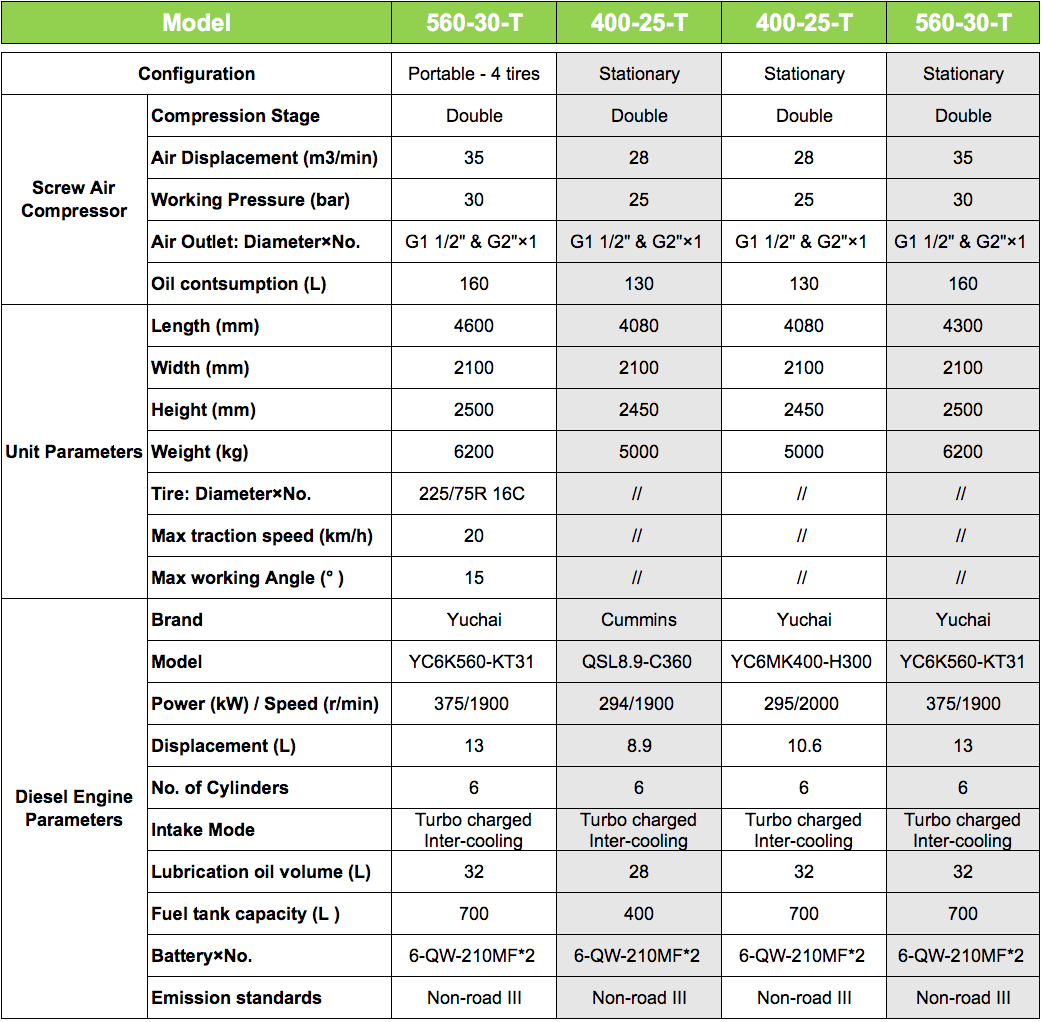

Air Pressure: 8~30 [bar]

Air Capacity: 3.7~35 [m³/min]

Power: 37~375 [kW]

Easy to Carry

Small, Lightweight, and Compact

Eco-friendly

Cost-Efficient

Available in Wide Range

Safety

Air Pressure: 8~30 [bar]

Air Capacity: 3.7~35 [m³/min]

Power: 37~375 [kW]

Easy to Carry

Small, Lightweight, and Compact

Eco-friendly

Cost-Efficient

Available in Wide Range

Safety

A one-fits-all strategy can’t be embraced for Portable Air compressors because the applications vary significantly with a slight difference in the structure.

Not sure about the mechanisms it’s based on or the underlying principle that it’s manufactured on?

This guide will cover it all, and the possible doubts and queries would be resolved.

Let’s delve into the subject in detail.

What Is Industrial Portable Air Compressor?

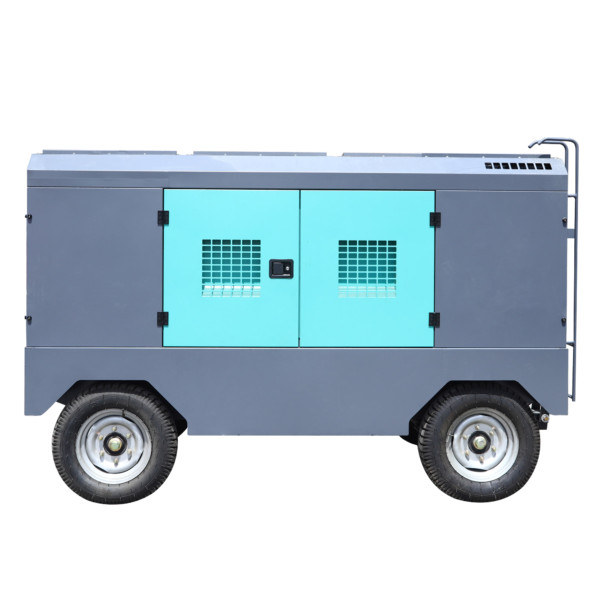

Portable Air Compressors offer the same functionality and operating capacity options as the other stationary industrial air compressors. However, they are smaller, lighter, compact, and portable. They also include some extra safety features to enhance portability and usability at remote construction sites or drilling sites.

These towable industrial compressors are designed for better reliability and longer life. They produce strong power with significantly lower fuel consumption. They are equipped with multi-stage air filters along with other features, making them suitable for dusty environments such as mining, drilling, agriculture, roadworks, and general constructions.

Besides, they also feature all-terrain wheels along with towing system and lift ring, making them easy to carry and move even on bad terrain conditions.

What Are The Types Of Industrial Portable Air Compressors?

The Industrial Portable Screw Air Compressors can be classified into two following categories:

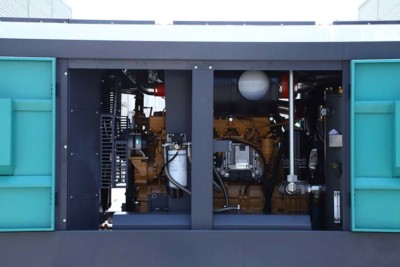

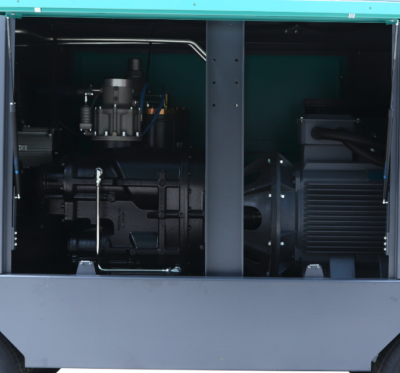

This type of Air Compressors features a heavy-duty and fuel-efficient diesel engine coupled with a state-of-the-art screw air compressing system.

It is equipped with a superior air filter with two-stage dust removal and filtering system for high air quality and extended service life of compressor parts. It gives the efficiency of up to 99.9% even in heavy-duty environments.

Besides, the device also features a high-quality oil filter with excellent oil purification capability. It is to ensure a clean and safe oil system for lubricating the oil screw air compressing system.

These towable diesel screw air compressors have a robust compressor shell and wear-resistant damped chassis, making them travel-friendly, portable, fire-proof, and sound-proof.

The diesel screw air compressor can further be classified into two categories:

This type of air compressor is powered by an electric motor instead of a diesel engine. Apart from it, almost all other features are the same as mentioned above.

The Electric power sources make these screw air compressors environment friendly and much cheaper to operate than diesel screw air compressors. They produce better air quality and require comparatively less maintenance. Besides, they produce no emission or noise and are relatively lightweight, small, and compact.

However, electric-powered air compressors are useless in remote areas with no electricity.

Is Towable Industrial Air Compressor Easy To Use?

These air compressors can be towed behind any vehicle and carried to the site without any problem. Next, you are required to fill the fuel tank with high-quality diesel and start it. Check the engine oil level and air and oil filter condition.

As diesel-powered engines emit gasses, they should be placed in a well-ventilated area, especially when using it for mining.

This electric Industrial Air Compressor features chassis with wheels and a towing mechanism which enables it to carry easily to the remote site.

Unlike Diesel Powered Air Compressor, these electric powered industrial air compressors feature a “Plug n Play” Operation. So you only require to plug in the power supply with 380V – 460V +/-10% Voltage to operate.

It is advised to directly plug in the power supply into the air compressor instead of using an extension cable to prevent the risk of a short circuit.

What are the uses of Industrial Air Compressors?

As stated above, the industrial air compressors are designed to yield high pressure to functionalize the machinery used at the sites mentioned below:

The nature of operations at the mining sites is massive, and to steer those tasks, air compressors are one of the most vital needs. The auxiliary fans, the blower fans, carriage systems, and all those ducts that function are run by the compressed air.

There always was a need for automated devices at these working sites to enhance the efficiency and productivity of the tasks. Industrial Air compressors direct the machines that perform the drilling, repairing, shafting, demolition, and several such tasks.

Agriculture is now not solely based on the archaic methods devised centuries ago. Now, the technologies have revolutionized over the years resulting in an advancement pushing the machinery to be used in vegetation and the spray of pesticides over the crops. Compressed air is being used to run these machines, which can be induced with MPAC or HPAC.

Industrial screw air compressors have numerous uses in mining. Sandblasting, powering jackhammers, and drill heads are among the most prominent ones.

What are the benefits of Industrial Portable air compressor?

Portable and towable industrial air compressors have the following benefits:

Unlike stationary industrial air compressors, these devices feature robust tires along with towing mechanisms, so they can easily attach to any vehicle and can be carried to remote sites like mining, construction, drilling, etc.

To assist its portability and usability, these towable industrial air compressors are smaller, lighter, and compact. This helps the users to use it in remote sites with small spaces.

The industrial air compressors, especially electric-powered ones, produce considerably less air and noise pollution, making it less hazardous for workers on the site.

The towable air compressors are designed to be fuel-efficient or energy-efficient and require less maintenance. It helps users use these machines for a more extended period and save considerable operation and maintenance cost.

They are available in various tank sizes and CFM and PSI capacities, making it easy for you to choose the variant that matches your budget and unique compressed air generation requirements.

The industrial portable air compressors are equipped with extra safety features, as they are designed for use in dangerous sites like mining and construction. Thus, you can use them fearlessly.

Conclusion

If you’ve been profane to the principles and the possible applications of Portable Industrial Air compressors and wondered how they even operate, then this guide must have cleared all the queries you’ve had.

The subject is no doubt complex, and we’ve presented it in a way even a non-specialist can digest the concepts and the terminologies being used in the text.

Rotary screw compressors are commonly used in commercial settings such as dry cleaning establishments. The rotary screw compressor

Rotary screw compressors are predicted to have a prominent role in the compressed air industry in the future.

Industrial air compressors are used in nearly every industry. Air is essential to many manufacturing processes, and compressed

When it comes to industrial equipment, vacuum pumps and air compression systems are two of the most critical

Air compressors are significant in various industries; it hasn't forsaken medicine and dentistry to illuminate with its sparkle.

In ancient times, mining was genuinely a hectic task to perform. Workers get on their wits end after

We replaced 21 piston type compressors with one 40bar 10cubic Screw type compressor.

No more noise, no more spare parts and high maintenance fee.

We began to use their oil free type products since 1998, the products are very reliable.

Their Water-lubricated Screw Air Compressor can ensure the 100% oil free and clean compressed air for our processing, and ensure the high quality of our products.

The oil free type screw air compressor energy saving 38.6% compared with our used air compressor, and saving 25.8% compared with the new oil lubricated type screw air compressors.

“Class 0 oil-free air compressor guarantee the best quality of our end products”

“Electrical costs and maintenance fee is significantly reduced.”